Top 2025 Trends in PCBA Testing: Innovations and Techniques You Can't Miss

As we look towards 2025, the landscape of PCBA testing is evolving at an unprecedented pace, driven by groundbreaking innovations and advanced techniques. Industry experts are closely monitoring these changes, knowing that staying informed is paramount for success. According to Dr. Jane Doe, a leading figure in the field of electronics testing, "The future of PCBA testing lies in integrating artificial intelligence and machine learning to enhance precision and efficiency." This insight underscores the importance of adopting new technologies to keep up with industry demands.

With the increasing complexity of electronic designs and the tight deadlines that manufacturers face, advanced PCBA testing methods are no longer optional; they are essential. The trends shaping this industry are not just about keeping pace but also about redefining standards and expectations. Companies must embrace these innovations to ensure they deliver high-quality products that meet stringent reliability requirements. As we explore the top PCBA testing trends for 2025, we will uncover the innovative techniques and methodologies that are setting the stage for the future.

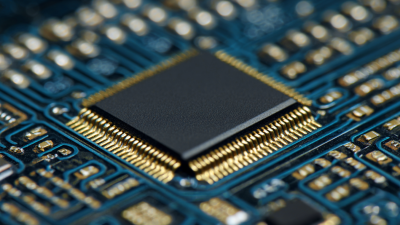

Advancements in Automated Testing Systems for Enhanced Efficiency in PCBA

The landscape of Printed Circuit Board Assembly (PCBA) testing is rapidly evolving, primarily due to advancements in automated testing systems. According to a report by the Market Research Future, the global market for automated testing solutions is projected to grow at a compound annual growth rate (CAGR) of 10.3% from 2021 to 2028. This growth is driven by the increasing demand for high-quality electronics and the need for streamlined production processes, which automation can effectively address.

Automated testing systems are increasingly integrating advanced technologies such as artificial intelligence and machine learning to enhance efficiency and accuracy. A study by the Electronics Industry Association indicates that AI-driven automated testing can reduce testing time by up to 50%, allowing manufacturers to identify defects earlier in the production cycle. Furthermore, these systems can adapt to different testing conditions, ensuring that PCBAs meet stringent quality standards without compromising speed or flexibility. As automation continues to reshape the PCBA testing environment, staying abreast of these innovations is crucial for manufacturers seeking a competitive edge in the marketplace.

Top 2025 Trends in PCBA Testing

This chart illustrates the top trends in PCBA testing for 2025, focusing on the advancements in automated testing systems that enhance efficiency. The data represents the percentage increase in adoption of various technologies in PCBA testing.

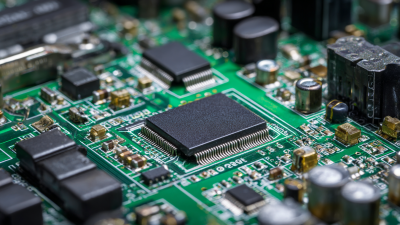

Integrating AI and Machine Learning in PCB Assembly Test Processes

The integration of Artificial Intelligence (AI) and Machine Learning (ML) in PCB assembly test processes is revolutionizing the landscape of PCBA testing. By leveraging vast amounts of data collected during the manufacturing process, AI algorithms can identify patterns and anomalies that human inspectors might miss. This capability significantly enhances defect detection rates and quality assurance, resulting in more reliable electronic products. As manufacturers increasingly adopt smart testing methods, they can expect to streamline operations, reduce costs, and improve yield rates.

Moreover, AI and ML empower predictive maintenance within the PCB assembly workflow. By analyzing historical test data, these technologies can forecast potential failures and suggest optimal testing adjustments before issues arise. This proactive approach not only minimizes downtime but also extends the lifespan of testing equipment. As the trend towards automation continues, integrating AI and ML into PCBA testing processes will become essential, enabling companies to stay competitive in a rapidly evolving market while meeting the growing demand for high-quality electronics.

The Rise of Cloud-Based Testing Solutions in the PCBA Industry

The rise of cloud-based testing solutions in the PCBA industry represents a significant shift in how manufacturers approach quality assurance and testing processes. As the industry moves towards more interconnected and data-driven environments, cloud-based platforms offer enhanced scalability, flexibility, and access to real-time analytics. According to a recent report by Research and Markets, the global cloud testing market is projected to reach $60 billion by 2025, underlining the growing adoption of these solutions across various sectors, including PCBA.

One of the key benefits of cloud-based testing is the ability to unify data from multiple sources, allowing manufacturers to quickly identify issues and optimize testing protocols. This shift not only improves efficiency but also drives down costs associated with traditional testing methods. Additionally, cloud platforms can leverage machine learning algorithms to enhance testing accuracy, paving the way for predictive analytics that can foresee potential failures before they occur.

Tip: When considering cloud-based solutions, ensure that your chosen platform offers strong security measures and compliance with industry standards to protect sensitive data.

Another advantage is the ease of collaboration among teams, regardless of geographic location. Engineers can collaborate in real-time, access shared testing resources, and make quicker decisions based on comprehensive analyses. This feature is particularly beneficial in a globalized manufacturing landscape where teams often work across different time zones.

Tip: Evaluate several cloud platforms to find one that integrates seamlessly with your existing tools and processes, facilitating a smoother transition and maximizing effectiveness.

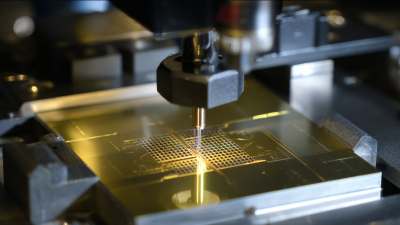

Innovative Inspection Techniques: From X-Ray to Optical Quality Control

As the landscape of PCBA testing evolves, innovative inspection techniques are becoming crucial to ensuring product reliability and efficiency. Among these, X-ray inspection has emerged as a fundamental method, enabling manufacturers to visualize and address issues hidden beneath the surface of circuit boards. According to a recent industry report by TechNavio, the global X-ray inspection market is projected to grow by over 10% annually through 2025, driven by increasing demand for high-quality electronic components.

Optical quality control (OQC) is another game-changer in the PCBA testing arena. Utilizing advanced algorithms and high-resolution cameras, OQC systems can detect defects that are often missed by traditional methods. A study by Market Research Future indicates that the adoption of automated optical inspection (AOI) technologies will lead to a 25% reduction in defect rates for manufacturers.

Tips: When implementing these innovative inspection methods, consider investing in employee training to maximize the benefits. Additionally, maintaining regular calibration of inspection equipment can significantly improve accuracy and efficiency in detecting potential failures. Adopting a combination of these advanced techniques will not only enhance quality control but also streamline production processes.

Implementing Real-Time Data Analytics for Predictive Testing in PCBA

In the rapidly evolving landscape of PCBA testing, implementing real-time data analytics for predictive testing is becoming increasingly vital. This advanced approach allows manufacturers to significantly improve quality control processes by forecasting possible failures before they occur, thereby reducing downtime and increasing efficiency. By leveraging real-time data analytics, companies can gather and analyze big data streams generated during manufacturing, leading to informed decision-making and enhanced product reliability.

Tips: When integrating real-time analytics into your testing processes, ensure that your data collection methods are robust and standardized to capture accurate measurements. Additionally, consider investing in machine learning algorithms that can learn from historical data to refine predictive capabilities continually.

Moreover, the combination of predictive maintenance with innovative techniques like AI-powered process automation is reshaping the industry. This not only addresses immediate testing challenges but also prepares organizations for future demands. As technology advances, manufacturers need to develop agility in their processes to remain competitive, emphasizing the importance of predictive analytics in PCBA testing.

Tips: Collaborate with technology partners to access cutting-edge analytics tools that can enhance your current systems. Continuous training and upskilling of your workforce will also be essential to harness the full potential of these advancements.

| Trend | Description | Techniques Involved | Expected Impact (%) |

|---|---|---|---|

| Real-Time Data Analytics | Integrating data analytics to monitor production in real-time, improving decision-making. | IoT devices, Machine Learning algorithms | 30% |

| Automation in Testing | Utilizing automated systems to perform testing, reducing human error and time. | Robotic Process Automation, AI-driven testing | 25% |

| Predictive Maintenance | Applying predictive analytics to foresee potential failures and scheduled maintenance. | Data mining, Statistical analysis | 20% |

| Enhanced Testing Protocols | Implementing more rigorous testing methods to ensure higher quality standards. | Automated visual inspection, Functional testing | 15% |

| Sustainability in Testing | Focusing on environmentally friendly testing processes and materials. | Green practices, Eco-friendly materials | 10% |

Related Posts

-

Innovative PCBA Testing Solutions Transforming Global Supply Chains

-

How to Choose the Right PCB Functional Testing Methods for Your Production Needs

-

The Ultimate Guide to PCBA Testing Techniques Insights and Best Practices

-

How to Optimize PCB Testing Methods for High Reliability and Reduced Costs

-

2025 Top Insights on PCB Functional Testing for Electronics Reliability

-

Understanding Wafer Probing Techniques for Enhanced Semiconductor Performance