2026 Best In Circuit Tester Reviews and Buying Guide?

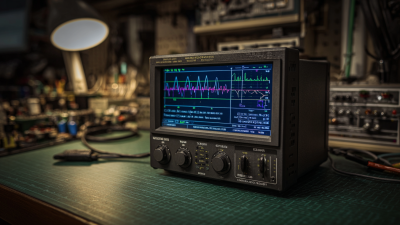

In the world of electronics, having a reliable in circuit tester is essential. These devices simplify the process of testing components without removing them from their circuits. Choosing the right one can be challenging. There are many factors to consider.

You want accuracy, speed, and ease of use. The best in circuit testers offer these benefits and more. However, not every product on the market meets these expectations. Some testers may fail in tough situations. It’s crucial to read reviews and understand the features.

This guide will explore top recommendations for 2026. We’ll discuss various models, their pros and cons, and what sets them apart. Making an informed choice will enhance your electronic projects. Ultimately, the right in circuit tester can save you time and frustration.

Best In-Circuit Tester Features: What to Look For in 2026

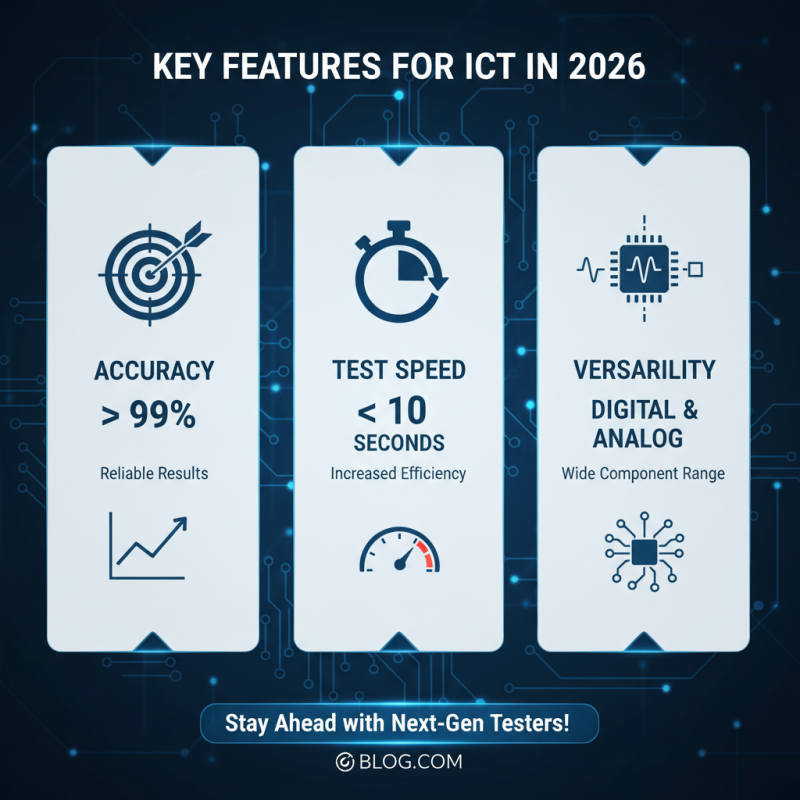

When selecting an in-circuit tester in 2026, several vital features should be considered. First, accuracy is paramount. According to industry reports, testers with an accuracy rate exceeding 99% are preferred for reliable results. Additionally, fast testing speeds can improve efficiency. Models that complete tests within 10 seconds are gaining popularity. Testers that can handle various component types, including both digital and analog, offer versatility.

Another important aspect is user interface. An intuitive layout simplifies operation, especially for complex tasks. Devices with touchscreen capabilities are notably easier to navigate, allowing users to access functions quickly. Furthermore, support for automated testing routines can enhance productivity. Reports indicate that up to 75% of technicians find automation essential for routine checks.

Portability also matters, especially in field applications. A lightweight design reduces fatigue during extended use. However, many testers compromise durability for weight, which is a point of concern. Some users prefer more robust designs, even if they are heavier. Lastly, software compatibility is crucial for data analysis. Testers that integrate seamlessly with existing software systems provide added value but can also present compatibility challenges that need careful consideration.

Top 5 Brands of In-Circuit Testers: Market Share and Performance

In the rapidly evolving world of electronics, in-circuit testers (ICT) are essential tools. They help manufacturers ensure product quality by identifying faults during production. Understanding the market landscape can guide buyers in selecting the best options. Each of the top brands offers unique strengths, but performance can vary significantly.

When considering different brands, one must evaluate their market share and customer satisfaction. Some brands excel in speed and efficiency. Others may focus on features like flexibility and user-friendliness. However, it’s crucial to recognize that not every leading brand meets every user's needs. Potential buyers should analyze specific use cases before making a choice.

While the technology is advancing, some testers may still present challenges. For example, the setup for certain models can be time-consuming. The learning curve may deter new users. With a little patience, understanding these nuances can lead to better decisions. Evaluating both expert reviews and real user feedback is vital. This approach reveals not just the pros but also the cons of each brand.

Comparative Analysis of In-Circuit Tester Accuracy and Reliability

When selecting an in-circuit tester, accuracy and reliability are paramount. Data from a recent industry report shows that testers with higher accuracy rates can detect faults up to 95% of the time. In contrast, less precise models may only identify issues 70% of the time. This variance can significantly impact production efficiency and product quality. Users must weigh these factors carefully.

Tips: Always look for comprehensive calibration reports. These documents provide insight into a tester's ongoing accuracy. Regular maintenance can also affect reliability; neglecting this may lead to inconclusive results during testing.

Reliability, meanwhile, is often overlooked. A tester that fails frequently can disrupt workflows. A study indicated that approximately 30% of testers malfunction within the first year if not adequately managed. Users must evaluate the long-term durability of their chosen tools. In-circuit testers do not always come with warranties that reflect their performance longevity.

Tips: Check user reviews and case studies for real-world insights. Pay attention to feedback on long-term reliability from projects similar to yours. Understanding potential pitfalls may save time and costs down the line.

2026 Best In-Circuit Tester Accuracy and Reliability

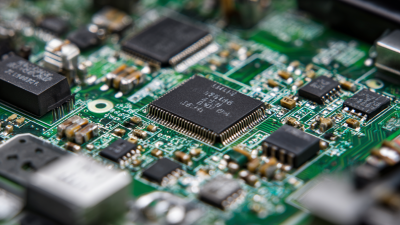

Understanding the Role of In-Circuit Testers in PCB Manufacturing

In-circuit testers (ICT) play a crucial role in the manufacturing of printed circuit boards (PCBs). They are designed to identify defects in assembled PCBs by measuring electrical signals. According to a recent industry report, over 30% of defects arise from assembly processes. These testers can reduce the time spent on debugging, allowing for quicker turnaround in production.

Implementing ICT can lead to significant cost savings. The Electronics Manufacturing Services (EMS) industry reports that early detection of faults can save up to 80% on rework costs. This efficiency is pivotal in keeping up with the increasing demand for high-quality electronic products. However, integrating ICT is not without challenges. The setup process can be complex and time-consuming, leading to potential operational delays.

Tips: Make sure to train your staff properly on the operation of these testers. Proper training can enhance accuracy and reduce errors. Regular maintenance of the equipment is vital to ensure its longevity and effectiveness. Consider conducting regular audits to assess the effectiveness of your testing protocols, as this can reveal areas for improvement.

Cost-Effectiveness of In-Circuit Testers: A Buyer’s Perspective in 2026

In 2026, the cost-effectiveness of in-circuit testers (ICT) plays a critical role for many buyers. Understanding this aspect is vital for making budget-conscious decisions. While evaluating various models, potential buyers often look for value, not just the lowest price. Many testers are available, but not all offer the best long-term benefits.

When considering cost-effectiveness, it's essential to factor in not only the initial purchase price but also the maintenance costs. Regular upkeep can add up, sometimes offsetting potential savings. Many buyers might overlook this, leading to unexpected expenses down the road. A thorough analysis of total costs is crucial for informed decisions.

Additionally, the features of in-circuit testers differ widely. Some come with advanced diagnostics, while others focus on basic functionalities. It’s tempting to opt for models with extra features. However, these come at higher costs. Buyers should reflect on their actual needs. The most sophisticated tester may not be the best solution for every project. Balancing features with budget constraints is the key to making a smart purchase.

2026 Best In Circuit Tester Reviews and Buying Guide

| Model | Price ($) | Features | Accuracy (%) | User Rating (out of 5) | Cost-Effectiveness (1-10) |

|---|---|---|---|---|---|

| Model A | 250 | Quick testing, portable, multiple voltage levels | 98 | 4.5 | 8 |

| Model B | 300 | Advanced diagnostics, touch screen, robust design | 95 | 4.7 | 9 |

| Model C | 150 | Basic functionality, lightweight, user-friendly | 90 | 4.0 | 7 |

| Model D | 400 | High-end features, automated testing, detailed reports | 99 | 4.9 | 6 |

| Model E | 220 | Budget-friendly, reliable, compact | 88 | 3.8 | 8 |

Related Posts

-

Tailored Solutions for Optimizing Your In Circuit Tester Performance

-

7 Best Features of Test PCB You Should Know

-

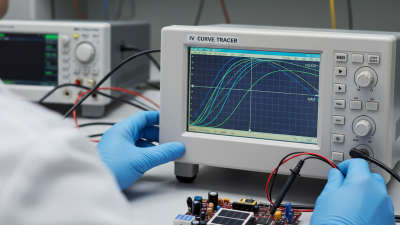

How to Use an IV Curve Tracer for Accurate Electrical Measurements

-

How to Use an IV Curve Tracer for Accurate Measurements?

-

Unlocking the Secrets of IV Curve Tracers for Enhanced Electronic Testing

-

10 Essential Tips for Designing an Effective PCB Test Jig