Best PCB Test Fixture Kit Options for Your Electronics Projects?

In the world of electronics, a reliable PCB test fixture kit is essential. These kits simplify testing and diagnosing circuit boards, making projects smoother and more efficient. A good fixture helps connect various components precisely. This precision can significantly impact the overall performance of your electronic devices.

Choosing the right PCB test fixture kit can be challenging. Options vary in price, quality, and features. Some kits may not offer the versatility you need. It's crucial to evaluate your specific project requirements before making a decision. Consider factors like size, compatibility, and ease of use.

Testing is a vital part of the design process. The right kit can save time and reduce errors. However, many overlook this important tool. They focus on components but ignore the fixture necessary for testing. Remember, a mismatch between the kit and your project can lead to frustration. Always reflect on your needs before purchasing.

Understanding PCB Test Fixtures and Their Importance

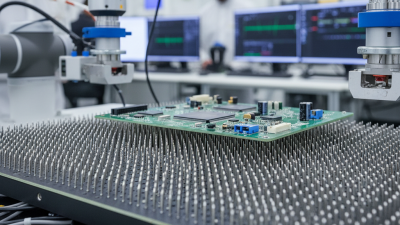

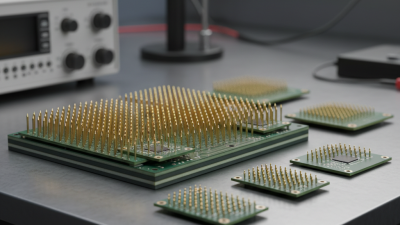

PCB test fixtures are essential tools in electronics projects. They allow for efficient testing of printed circuit boards (PCBs) and help reduce errors. These fixtures hold the PCB securely in place. They facilitate electrical connections for testing purposes. Proper fixtures also ensure accurate measurements during evaluation.

Understanding their importance is crucial. A good test fixture can save time and effort. They enhance the reliability of test results. Without a proper fixture, testing can become challenging. Issues like poor contact and misalignment may arise. These problems can lead to failed tests or false readings. Reflecting on the fixture design is important. It must cater to specific project requirements. Not all projects are alike. Adapting your fixture can significantly improve outcomes.

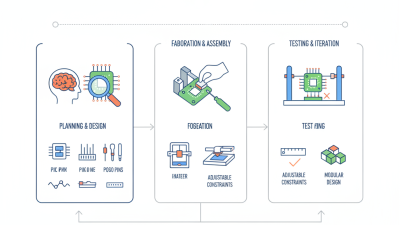

Incorporating customizable elements in a test fixture can be beneficial. Different PCB layouts require different setups. Experimentation with various designs is often necessary. This trial-and-error process can be frustrating. Mistakes may occur, but each one offers valuable lessons. Ultimately, a well-thought-out test fixture can streamline your electronics projects.

Importance of PCB Test Fixtures in Electronics Projects

Different Types of PCB Test Fixture Kits Available

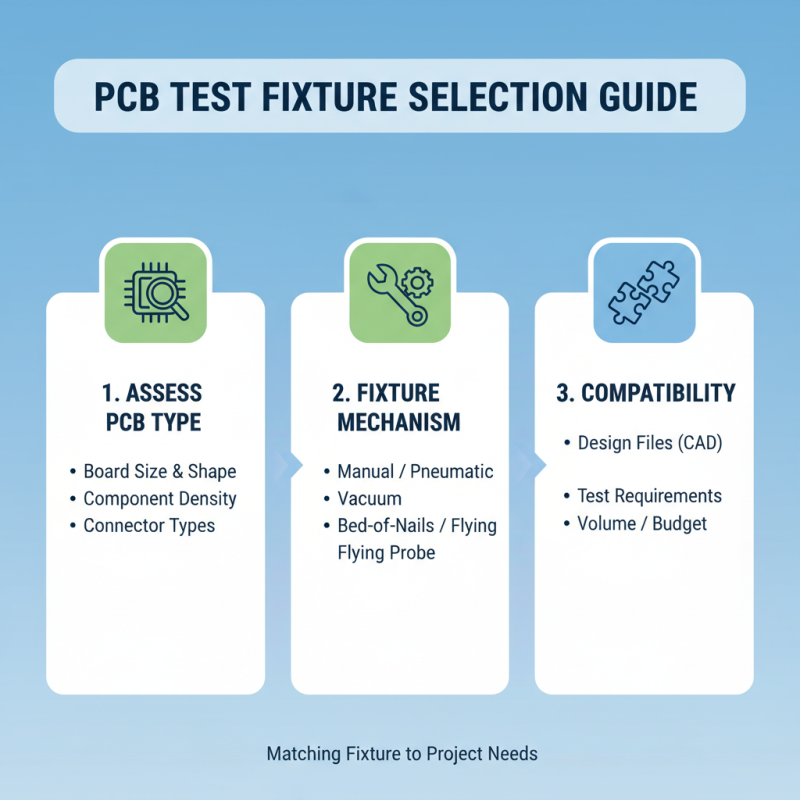

When selecting a PCB test fixture kit, it's crucial to understand the various types available. These kits vary based on their configuration and the specific requirements of your electronics project.

Modular kits, for example, offer flexibility and can be customized to fit different PCB sizes. According to a recent industry report, about 45% of engineers prefer modular setups for their adaptability in testing various boards.

Another type is the fixed test fixture, which is designed for specific layouts. These fixtures provide precision and stability during testing, which help in reducing error margins significantly. A study revealed that utilizing fixed fixtures improved testing efficiency by 30%, highlighting their importance in high-volume production environments. However, they lack the versatility that modular kits provide, limiting their use in diverse project scenarios.

Ai technology plays a role in improving these testing processes, yet there are still challenges. A significant number of engineers report difficulty in aligning their projects with the right fixtures. This often stems from the rapid technological advancements outpacing fixture development. As a result, many testers find themselves reflecting on their choices and the impacts on their project's timeline.

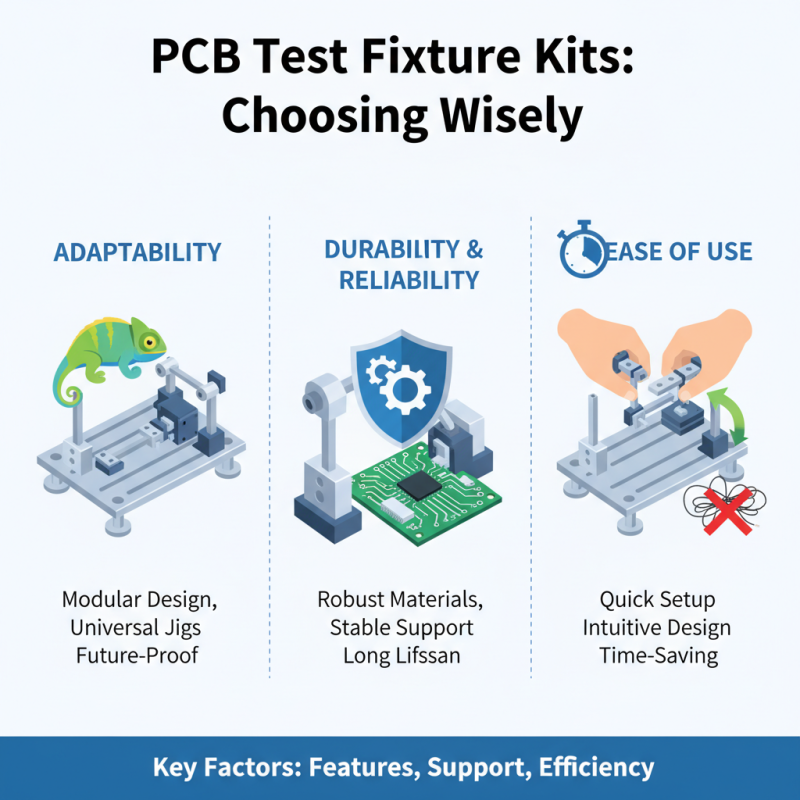

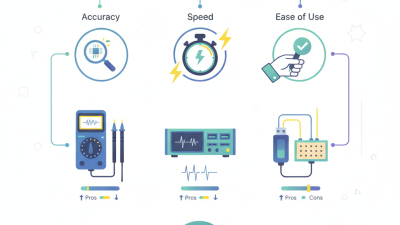

Key Features to Look for in a PCB Test Fixture Kit

When selecting a PCB test fixture kit, certain key features stand out. Flexibility is essential. A good kit allows various PCB sizes and types. It should adapt to different testing requirements. Typically, a modular design achieves this well, accommodating various test scenarios. Look for features that support thermal management, too. Heat dissipation can affect measurements. A well-designed fixture helps maintain accuracy.

Another important aspect is the quality of the connectors. Reliable connectors ensure consistent electrical performance. According to industry reports, nearly 20% of test failures can be traced back to poor connections. Investing in high-quality connectors will improve results. Testing speed also matters. Efficient setups reduce downtime. Speeding up time to market can provide a competitive edge.

Finally, consider the ease of use. Complex setups can lead to errors. User-friendly assembly instructions are a plus. Training staff to use the fixtures efficiently is crucial. Yet, many companies overlook this aspect. Poor training leads to wasted time and resources. Be cautious about assuming your team will navigate a complicated system effortlessly. Reflecting on these features will guide you in making the best choice for your projects.

Best PCB Test Fixture Kit Options for Your Electronics Projects

| Feature | Description | Importance |

|---|---|---|

| Adjustable Jigs | Allows for easy adaptation to various PCB sizes and shapes. | High |

| Material Quality | Durable materials prevent wear and ensure longevity of fixtures. | High |

| Compatibility | Works with different PCB sizes and testing equipment. | Medium |

| Ease of Use | Simple setup and operation to save time during testing. | High |

| Portability | Lightweight and easy to transport for field testing. | Medium |

| Probe Access | Allows for easy connection to testing probes without obstructions. | High |

| Testing Range | Supports a wide range of electrical tests and measurements. | High |

Comparative Analysis of Top PCB Test Fixture Kit Brands

When choosing a PCB test fixture kit, understanding the available options is crucial. Many brands offer various features, targeting different needs. Some kits focus on adaptability, while others emphasize durability. A good test fixture should provide solid support for your boards, yet some may fall short in reliability. A fixture that is easy to set up can save time, but if it’s complex, it can lead to frustration.

Not all brands prioritize user experience. Some may offer flashy features that aren't very useful. Simplicity can be more effective. Consider the ease of integration with existing tools. Sometimes, the most straightforward solution is overlooked. However, don't just rely on product reviews. Handling the fixture can reveal its true quality. Common pitfalls include insufficient clamps or poor contact points, which can affect your testing results.

Price is another important factor. A higher price doesn’t always mean better quality. Some affordable options deliver dependable performance. But watch out for hidden costs. Accessories might not be included, adding to the overall expense. Be mindful when assessing value. The right kit can enhance your workflow, but ensure it aligns with your project needs. Amateur mistakes often stem from overlooking these details, leading to wasted efforts and resources.

Tips for Choosing the Right PCB Test Fixture for Your Projects

When selecting a PCB test fixture, consider your project’s specific needs. Assess the type of PCBs you'll be working with. Different boards require different fixations and measurements. Pay close attention to compatibility. Not all fixtures work with all PCB designs.

Look for adjustable features. These can be crucial for testing different PCB sizes or types. Flexibility is essential. It allows you to reuse the fixture for various projects. Balance ease of use with functionality. A complex fixture might be a hassle, especially for newcomers.

Think about the materials used. Sturdier fixtures may cost more, but they last longer. Keep in mind the potential for wear and tear. Test fixtures should resist damage during repeated use. Don’t overlook ease of setup. A complicated setup process can waste valuable time. Make sure you can quickly and accurately position your boards.

Related Posts

-

Top 10 Tips for Using a Bed of Nails Test Fixture?

-

2026 How to Build a PCB Test Jig for Effective Testing and Prototyping?

-

Top 10 Benefits of Using Pogo Pin Test Fixtures?

-

The Ultimate Guide to Selecting the Right PCB Test Equipment for Your Needs

-

2026 Best In Circuit Tester Reviews and Buying Guide?

-

Essential Curve Tracer Tips for Accurate Electronics Testing and Analysis