How to Choose the Best Benchtop Pneumatic Press for Your Needs

When it comes to selecting the optimal benchtop pneumatic press for your specific applications, understanding the unique features and capabilities of these machines is crucial. "A well-chosen benchtop pneumatic press can elevate your productivity and precision," states Dr. James Carter, a leading expert in industrial machinery. His emphasis on thoughtful selection resonates with many professionals navigating the diverse offerings in the market today.

Choosing the right benchtop pneumatic press requires an assessment of various factors, including material compatibility, pressure capacity, and workspace requirements. The versatility of these presses makes them invaluable in numerous fields, from manufacturing to small-scale crafts. As industries continue to evolve, the ability to tailor machinery to fit specific operational needs has become not just advantageous, but essential for maintaining a competitive edge.

In this consideration process, it’s vital to recognize that the best benchtop pneumatic press is not merely the most powerful or expensive model, but rather the one that seamlessly integrates into your workflow, meeting both your current demands and future project aspirations. As you delve into the specifics of what a benchtop pneumatic press can offer, remember that the right choice is a combination of informed decision-making and understanding your unique operational context.

Understanding Benchtop Pneumatic Presses and Their Applications

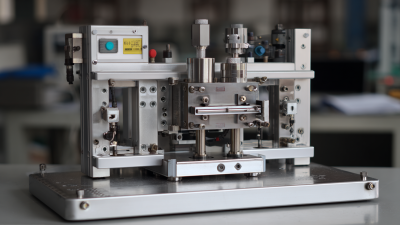

Benchtop pneumatic presses are versatile tools commonly used in various industries, including manufacturing, woodworking, and metalworking. These machines operate using compressed air to apply force efficiently, making them ideal for tasks that require precision and consistency. Their ability to handle a wide range of applications, such as assembly, clamping, and forming, allows them to serve multiple functions on a single workstation, which is especially beneficial for small to medium-sized operations.

When selecting a benchtop pneumatic press, it's essential to understand the specific applications you intend to use it for. Different models offer varying force capacities, stroke lengths, and features tailored for specific tasks. For instance, a press with a higher force capacity may be necessary for heavy-duty tasks, while lighter applications may only require a machine with moderate force.

Additionally, considering the size of the workpieces and the space available in your workshop is crucial, as well as assessing whether you'll need interchangeable tooling for different processes. By aligning the features of the pneumatic press with your project requirements, you can enhance productivity while ensuring safety and efficiency in your workspace.

Key Features to Consider When Choosing a Benchtop Pneumatic Press

When selecting the best benchtop pneumatic press for your needs, several key features should be taken into account to ensure optimal performance and suitability for your projects. First and foremost, the maximum pressure rating is critical. Depending on the materials you plan to work with, look for a model that can handle the specific pressures necessary for efficient operation. A pneumatic press with adjustable pressure settings offers flexibility, allowing you to customize the force applied for different tasks.

Another important consideration is the size and weight of the benchtop pneumatic press. Ensure that the machine fits comfortably in your workspace and is lightweight enough for easy maneuverability, while still being robust enough to handle the intended workload. Additionally, the size of the pressing area should match the dimensions of the objects you will be working with; too small a surface can limit your projects, while an excessively large one might waste space. Finally, pay attention to safety features, such as emergency shut-off functions and protective enclosures, as these can provide crucial safeguards during operation.

Assessing Power and Pressure Requirements for Your Projects

When selecting a benchtop pneumatic press, one of the most critical factors to consider is your specific power and pressure requirements. Different projects necessitate varying levels of pressure; thus, understanding the typical materials and tasks you will be handling is crucial. For example, if you're working with softer materials or conducting light assembly tasks, a lower pressure model may suffice. On the other hand, harder materials or tasks that require more force will demand a pneumatic press capable of delivering higher pressure levels. Analyzing your project's demands ensures you choose a machine that efficiently meets your needs without overextending your budget or capabilities.

Another key aspect to assess is the capacity of the pneumatic press in relation to your project scale. A press with adjustable pressure settings can offer more versatility, allowing you to tackle a range of tasks without needing multiple tools. Additionally, consider the overall design and construction of the press. A robust build is essential for maintaining consistent performance under pressure, while safety features such as pressure gauges and relief valves play a vital role in mitigating risks during operation. Prioritizing these power and pressure requirements will lead to a more productive setup tailored to your workshop's specific applications.

How to Choose the Best Benchtop Pneumatic Press for Your Needs - Assessing Power and Pressure Requirements for Your Projects

| Model | Max Pressure (psi) | Power (HP) | Piston Area (sq. in.) | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | 150 | 2 | 3 | 45 | 500 |

| Model B | 200 | 3 | 4 | 60 | 700 |

| Model C | 180 | 2.5 | 3.5 | 50 | 650 |

| Model D | 220 | 4 | 5 | 70 | 800 |

Evaluating Material Compatibility and Size Limitations

When selecting a benchtop pneumatic press, material compatibility is a crucial aspect to consider. Different materials require different pressure levels and have varying tolerances, which can affect the effectiveness of the press. For instance, softer materials like foam or fabric may require lower pressure settings to avoid damage, while harder materials such as metal or wood need higher pressures to achieve the desired results. It's essential to evaluate the types of materials you plan to work with and ensure that the pneumatic press can accommodate their specific requirements without compromising the quality of your work.

In addition to material compatibility, size limitations play a significant role in your decision-making process. The working area of the pneumatic press should match the dimensions of the materials you intend to work with. Consider both the maximum size of the materials and the depth of the press when evaluating your options. A larger workspace allows for greater versatility, enabling you to tackle various projects, while a compact design may be more suitable for smaller, intricate tasks. Assessing your workspace and project requirements will guide you in choosing a pneumatic press that not only fits your needs but also enhances your efficiency and productivity.

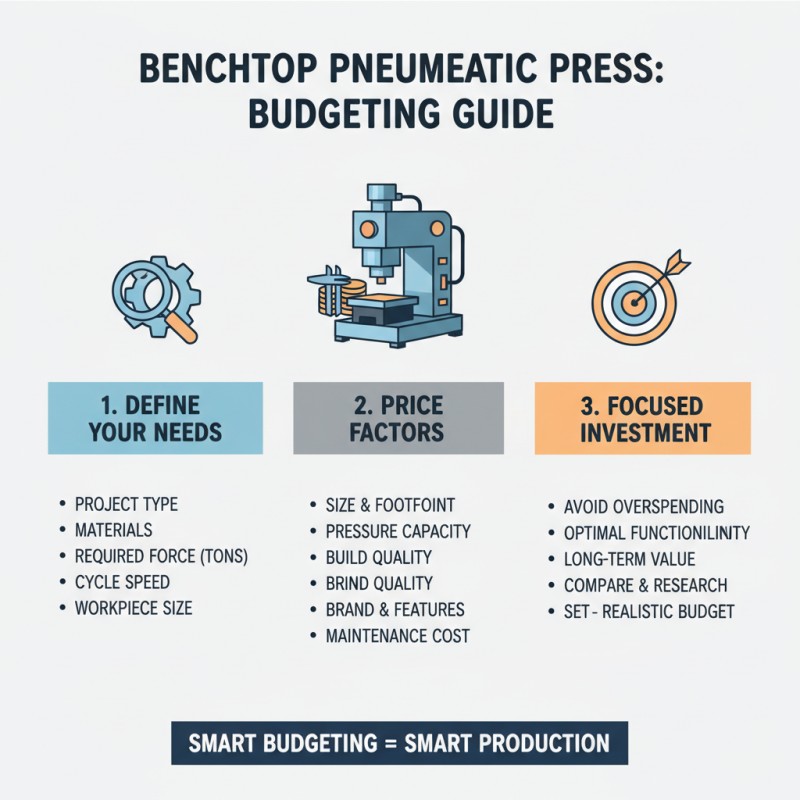

Budgeting and Cost Factors for Benchtop Pneumatic Presses

When considering the purchase of a benchtop pneumatic press, budgeting is a crucial factor that can influence your overall satisfaction and functionality. The first step in budgeting is to define your specific needs and the capacity required for your projects. This will help you avoid overspending on features or power that you might not utilize. Prices can vary widely based on size, pressure capacity, and construction quality, so having a clear idea of what you need will assist you in making a more focused investment.

Another critical aspect of budgeting is to consider the long-term operational costs associated with a pneumatic press. This includes ongoing expenses like air compressor maintenance, energy consumption, and potential repairs or replacements. While a lower initial purchase price may be tempting, it is essential to evaluate the overall cost-effectiveness of the unit. Sometimes investing a bit more upfront in a quality machine can result in savings over time due to increased efficiency and durability. Always weigh the initial costs against these potential future expenses to make a well-informed decision that meets both your financial and operational needs.

Related Posts

-

Unlocking Precision: How Benchtop Pneumatic Presses Revolutionize Small-Scale Manufacturing in 2023

-

Understanding the Importance of Semiconductor Testing in Modern Technology

-

2025 Top 10 Burn In Socket Solutions for Enhanced Thermal Performance and Reliability

-

How to Optimize Your Bed of Nails Test Fixture for Maximum Efficiency

-

5 Innovative PCB Test Fixture Solutions for Efficient Circuit Board Testing

-

Why Choosing the Right PCB Test Jig is Crucial for Your Manufacturing Success