How to Choose the Right PCB Functional Testing Methods for Your Production Needs

In today's rapidly evolving electronics industry, the importance of stringent quality control measures cannot be overstated, particularly when it comes to PCB functional testing. As per a recent industry report from IPC, nearly 70% of manufacturers believe that effective functional testing can significantly reduce costs associated with product failures and recalls. With the global printed circuit board market projected to exceed $100 billion by 2026, selecting the right testing methods is crucial to ensure reliability, performance, and compliance with industry standards. Various testing techniques, such as in-circuit testing (ICT), automated optical inspection (AOI), and functional testing, each offer unique benefits and challenges. This guide aims to navigate through these options, helping manufacturers align their production needs with the appropriate PCB functional testing methods, ultimately enhancing their product quality and market competitiveness.

Identifying Your Production Requirements for PCB Testing

Identifying your production requirements for PCB testing is crucial in ensuring quality and reliability in electronic products. According to a report by IPC, over 60% of manufacturers cite quality assurance as a major factor influencing their testing methodologies. Understanding whether your PCB will serve high-volume consumer markets or specialized industrial applications can help tailor your testing approach. For example, high-volume products may benefit from automated testing methods, while applications requiring stringent reliability may necessitate more comprehensive functional testing.

Furthermore, production requirements often dictate the complexity and scalability of your testing methods. A White Paper from the IEEE highlights that 35% of PCB failures occur due to insufficient functionality testing during production phases. This underscores the necessity of integrating methods that align with specific production goals, such as in-circuit testing for faster diagnostics or functional testing for more thorough validation. By clearly identifying your production needs upfront, you can select the right testing methods that not only enhance quality but also optimize operational efficiency, thus reducing potential costs associated with post-production failures.

Understanding Different PCB Functional Testing Methods

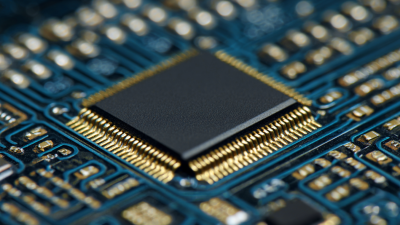

When selecting the appropriate PCB functional testing methods, understanding the various available techniques is essential for meeting production needs. Different functional testing methods, such as In-Circuit Testing (ICT) and Automated Optical Inspection (AOI), offer distinct advantages in terms of coverage and accuracy. Recent advancements in ICT systems have shown a significant improvement in detecting manufacturing defects, increasing overall reliability and cost-efficiency. A study highlighted that adopting a deep learning framework could enhance defect classification, leading to rapid detection of issues during production, where traditional methods might struggle.

Moreover, the integration of technologies such as Lab-on-PCB and micro-total analysis systems (µTAS) has revolutionized how functional testing can be approached, especially in environments where miniaturization is crucial. For example, a paper noted advancements in PCB surface defect detection using contextual attention mechanisms, which help in minimizing false detections and improving precision. These innovations not only help in ensuring product quality but also support the scalability of manufacturing processes, particularly as PCB designs become more complex and compact.

PCB Functional Testing Methods Comparison

This chart presents a comparison of different PCB functional testing methods based on their effectiveness and cost. The methods compared include In-Circuit Testing (ICT), Automated Optical Inspection (AOI), and Functional Testing (FT). The effectiveness is rated on a scale from 1 to 10, with 10 being the most effective.

Evaluating the Pros and Cons of Each Testing Method

When selecting the right PCB functional testing methods for your production needs, it's essential to evaluate the pros and cons of each available option. One of the most common methods is Automated Optical Inspection (AOI). This technique provides a non-contact way to inspect PCBs, making it efficient in identifying surface issues. However, while AOI is exceptionally fast, it may miss certain defects, particularly those occurring on internal layers or connections that are not visible on the surface.

Another popular choice is In-Circuit Testing (ICT), which allows for a detailed assessment of the electrical performance of components. This method offers high accuracy in detecting faults, thus minimizing the risk of defective products reaching the market. However, the complexity and cost of setting up ICT can be a significant drawback, especially for smaller manufacturers or those with limited production runs. Balancing the effectiveness of these testing methods with the associated costs and production speed is crucial for optimizing your PCB manufacturing process.

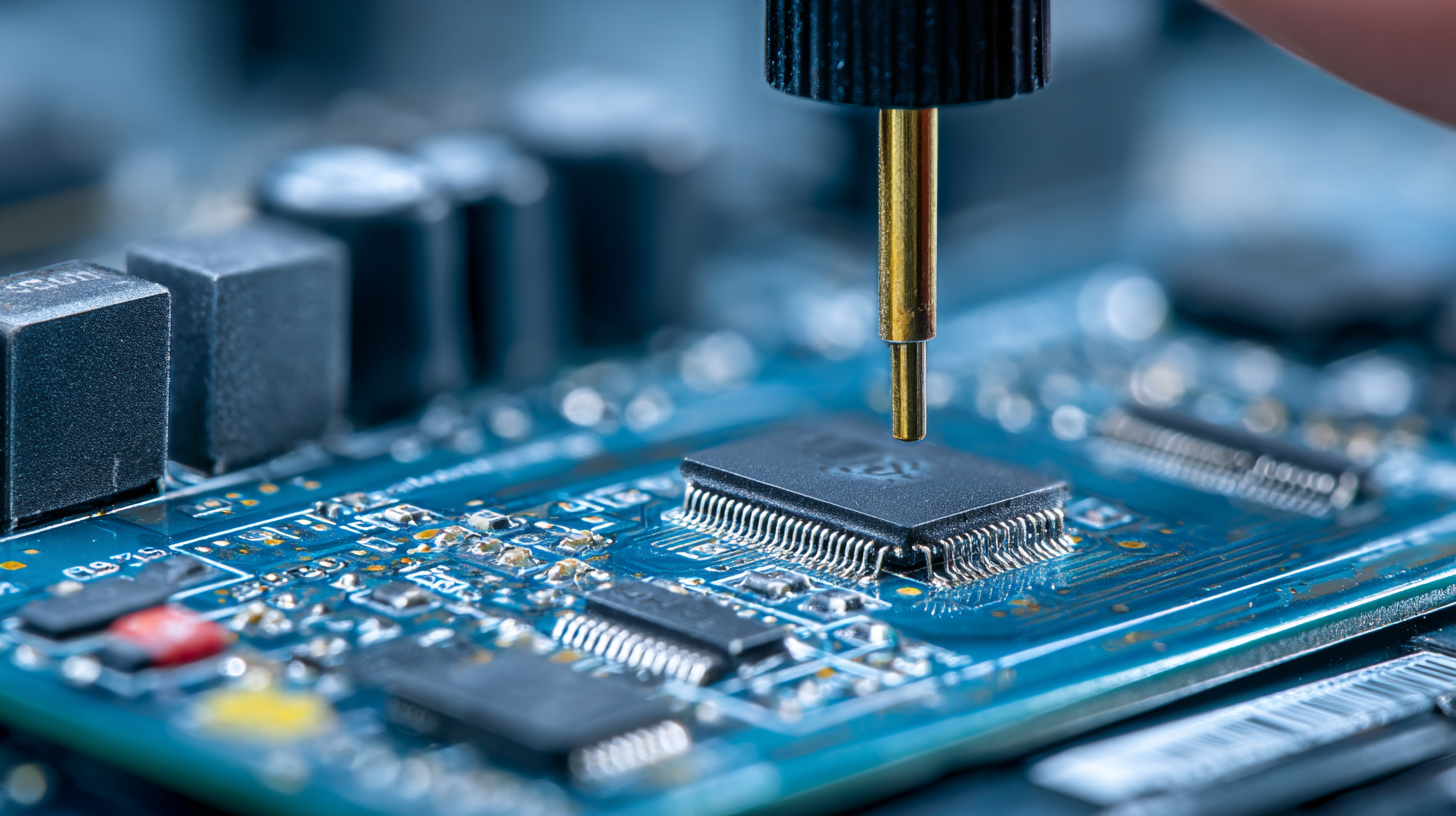

Integrating Automation in PCB Functional Testing

Incorporating automation into PCB functional testing can significantly enhance efficiency and accuracy in the production process. Automated testing systems, equipped with advanced sensors and software, allow for consistent and reliable evaluations of PCB performance. This technology reduces the risk of human error, ensuring that each unit is tested under the same conditions, which is critical for maintaining quality standards. Furthermore, automation can significantly speed up the testing process, enabling manufacturers to scale production without compromising on reliability.

To successfully integrate automation into PCB functional testing, it’s essential to choose the right tools and methodologies that align with specific production needs. Factors such as the complexity of the PCB design, the nature of the functional tests required, and the desired throughput must be considered. Additionally, investing in programmable hardware and flexible test software can provide the adaptability needed for future product generations. By leveraging automation, companies can not only improve testing accuracy but also gain valuable insights from the data collected, guiding further enhancements in design and production practices.

How to Choose the Right PCB Functional Testing Methods for Your Production Needs - Integrating Automation in PCB Functional Testing

| Testing Method | Automation Level | Cost | Speed | Accuracy |

|---|---|---|---|---|

| In-Circuit Testing (ICT) | High | $$$ | Fast | High |

| Functional Testing | Medium | $$ | Medium | Medium |

| Boundary Scan Testing | High | $$$ | Fast | High |

| Automated Optical Inspection (AOI) | High | $$ | Fast | Medium |

| Flying Probe Testing | Low | $ | Slow | Medium |

Making the Final Decision: Factors to Consider for Your PCB Testing Method

When choosing the right PCB functional testing methods for your production needs, several critical factors come into play. One of the most significant considerations is the complexity of the PCB design. For intricate designs with multiple layers and components, more sophisticated testing methods such as Automated Optical Inspection (AOI) or In-Circuit Testing (ICT) may be necessary to ensure every function performs correctly. Simpler designs might only require functional testing, which verifies the board operates as intended without needing detailed analysis of each component.

Additionally, the production volume can greatly influence your decision. High-volume production environments may benefit from automated testing solutions, which enhance efficiency and consistency. Conversely, lower volume runs might be better suited to manual testing methods, allowing for more flexibility and the ability to adapt to design changes without the need for extensive reconfiguration of testing equipment. Ultimately, balancing the complexity of the PCB with the expected production volume will guide you in selecting the most effective testing methodology, ensuring quality while optimizing resources.

Related Posts

-

How to Optimize PCB Testing Methods for High Reliability and Reduced Costs

-

The Evolution of PCB Test Fixtures Shaping the Future of Electronics Manufacturing

-

Innovative PCBA Testing Solutions Transforming Global Supply Chains

-

The Ultimate Guide to PCBA Testing Techniques Insights and Best Practices

-

The Ultimate Guide to Selecting the Right Semiconductor Test Socket for Your Needs

-

Understanding the Importance of Custom Test Fixtures in Product Development