Why Choose Pogo Pin Array for Your Connectors and Interfaces?

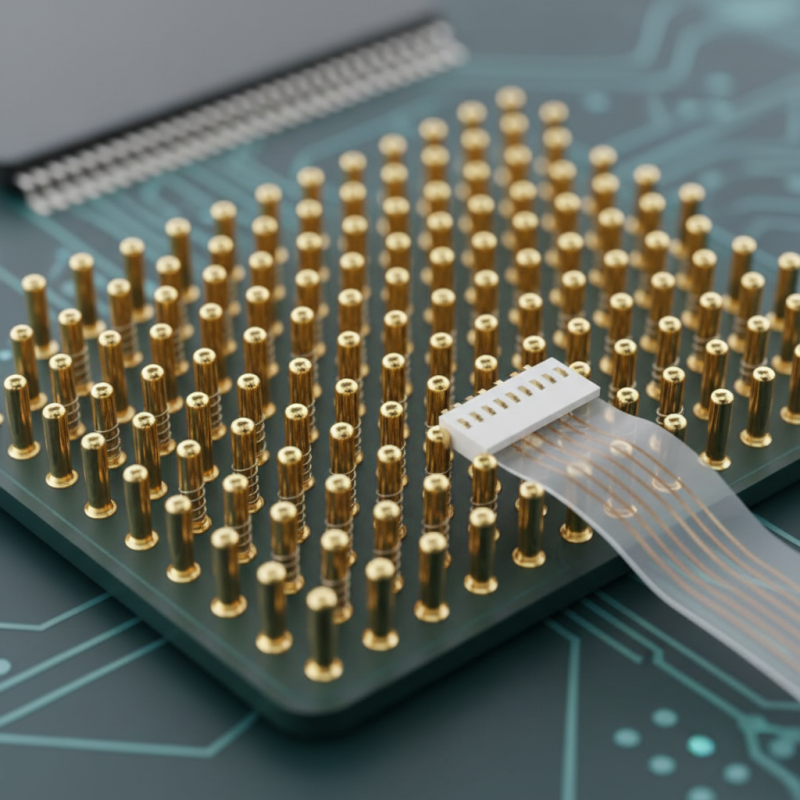

When choosing connectors and interfaces, the pogo pin array stands out. This technology offers unique advantages in various applications. Its compact design allows for high-density connections, making it ideal for modern electronics.

The pogo pin array excels in reliability. These pins provide excellent conductivity, even under pressure. This ensures stable connections over time. Users often appreciate the ease of integration with different devices. However, maintaining proper alignment can be a challenge. This is an aspect that design engineers must consider carefully.

Another important factor is the durability of pogo pin arrays. They can withstand numerous insertions and extractions. However, users should not overlook regular maintenance to prevent wear. Adopting pogo pin arrays can enhance your product's performance. Thus, making a thoughtful choice in this area is essential.

Benefits of Using Pogo Pin Arrays in Connectors and Interfaces

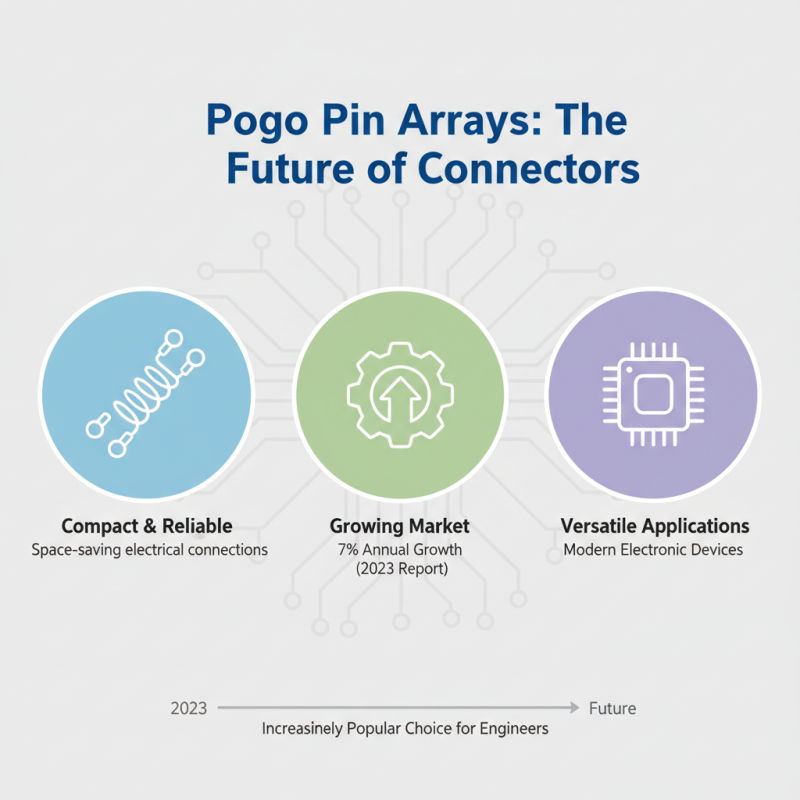

Pogo pin arrays are becoming increasingly popular in various connector applications. Their unique benefits make them an attractive choice for engineers and designers. For instance, these connectors provide reliable electrical connections in compact spaces, essential in modern electronic devices. A 2023 market report indicates that the Pogo pin industry is expected to grow by 7% annually, underscoring their rising importance.

One notable advantage of Pogo pin arrays is their ability to withstand thousands of connection cycles. This durability is significant in applications where frequent connection and disconnection occur, such as in consumer electronics. According to recent studies, about 70% of users consider durability a critical factor in connector selection. Furthermore, Pogo pins can maintain consistent performance under varying environmental conditions, which is crucial for products exposed to harsh atmospheres.

Despite their benefits, there are challenges. Pogo pin arrays can be more complex to design than conventional connectors. Engineers must carefully consider the pin alignment and materials used. Misalignment can lead to intermittent connections, impacting performance. Understanding these nuances is vital for successful implementation. The industry must continuously innovate to address these challenges while maximizing the advantages of Pogo pin technology.

Design Versatility: Customizing Pogo Pin Arrays for Various Applications

Pogo pin arrays offer impressive design versatility, making them ideal for various applications. These connectors can be customized in countless ways. You can adjust pin length, spacing, and layout. This adaptability ensures they fit seamlessly into different devices.

In practice, you might face challenges when customizing pogo pin arrays. It's vital to balance size and functionality. Too small a pin may reduce durability. Conversely, larger pins could take up unnecessary space. Ensuring a proper fit is crucial for reliable connections.

Consider the various industries that can benefit from pogo pin arrays. From consumer electronics to medical devices, the applications are vast. Custom designs can enhance performance while meeting specific requirements. These connectors can adapt to the unique needs of each project, providing solutions that are both creative and efficient.

Performance Advantages: Conductivity and Reliability of Pogo Pins

Pogo pin arrays are increasingly popular for connectors and interfaces due to their excellent performance. One key advantage is their conductivity. Pogo pins maintain a consistent and stable connection. This is crucial in high-frequency applications. Many users praise the reduced signal loss. However, some have reported issues with pin wear over time. This is an area for improvement.

Reliability is another significant factor. Pogo pins are designed for frequent connection and disconnection. They can endure many cycles without failing. This makes them ideal for applications like testing. Users often find they operate well in various environmental conditions. Nevertheless, ensuring proper alignment is essential to prevent connection issues.

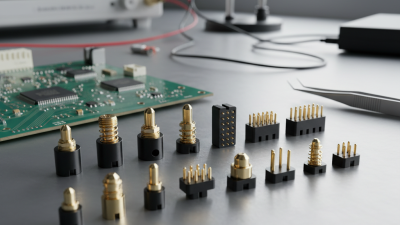

Tips: When choosing pogo pins, consider the type of material. Different metals offer varied conductivity levels. Regular maintenance can also extend the lifespan of your connectors. Evaluating the application's needs is critical. Don't overlook the impact of temperature on performance. Keeping these factors in mind will help optimize your design.

Why Choose Pogo Pin Array for Your Connectors and Interfaces? - Performance Advantages: Conductivity and Reliability of Pogo Pins

| Feature | Description | Advantages |

|---|---|---|

| Conductivity | High conductivity materials ensure efficient signal transfer. | Reduced signal loss and improved device performance. |

| Reliability | Designed for repetitive use with minimal wear and tear. | Longer device lifespan and lower maintenance costs. |

| Flexibility | Can accommodate various connector designs and configurations. | Versatile application in multiple devices and systems. |

| Performance | Optimized for high-speed data transfer and charging. | Enhanced user experience with fast and reliable connections. |

| Size Options | Available in various sizes to fit different applications. | Allows for compact designs without compromising performance. |

Comparative Analysis: Pogo Pin Arrays vs. Traditional Connectors

Pogo pin arrays present a unique approach to connectors and interfaces. These components are designed for precision and reliability. In contrast, traditional connectors often struggle with wear and tear. Pogo pins can flex and adapt. This feature enhances their lifespan and overall performance.

In practical applications, pogo pins are often used in test fixtures and battery connections. Their ease of use is a significant advantage in fast-paced environments. Traditional connectors can be cumbersome. They sometimes require tools to connect or disconnect. Pogo pin arrays, however, facilitate quick assembly, saving time and effort. This flexibility can lead to streamlined operations.

Yet, not all scenarios favor pogo pins. Their design may not handle high voltage as well as some traditional connectors. This limitation can raise concerns for strict applications. Users need to assess their requirements carefully. Overall, both systems have their strengths and weaknesses. The choice hinges on the specific needs of the application.

Comparative Analysis of Pogo Pin Arrays vs. Traditional Connectors

Cost Efficiency and Manufacturing Considerations for Pogo Pin Arrays

When selecting connectors and interfaces, cost efficiency is crucial. Pogo pin arrays offer a practical solution for manufacturers. They can optimize assembly processes. This can lead to lower labor costs and reduced errors during production. Simplifying designs can also cut expenses on raw materials. However, careful planning is needed to avoid oversights.

Manufacturing considerations play a significant role in choosing pogo pin arrays. These components can be assembled quickly, which saves time. Yet, some may overlook the importance of quality control. Ensuring that each pin meets specifications is essential for performance. Neglecting this aspect can result in failures down the line.

Additionally, pogo pin arrays allow for greater design flexibility. They can fit various applications, from consumer electronics to industrial devices. This versatility offers efficiency but can tempt designers to rush decisions. Balancing speed and quality is vital. Sometimes, taking additional time for evaluation and testing can yield better long-term outcomes.

Related Posts

-

Exploring the Benefits of Pogo Pin Arrays in Modern Electronics Design

-

Top Strategies for Optimizing Your Pogo Pin Array Performance

-

What Are Pin Pogo Connectors and Their Applications in Modern Electronics?

-

How to Choose the Right Pogo Pins for Your PCB Design Needs

-

What is the Importance of Pogo Pin Receptacles in Modern Electronics

-

Top 10 Pogo Pin Receptacles You Need for Your Electronic Projects