Top Custom Test Fixtures for Enhanced Testing Efficiency and Accuracy

In the realm of product testing and quality assurance, the importance of precision and efficiency cannot be overstated. As technology advances, so does the complexity of the products we develop, making custom test fixtures a crucial element in the testing process. Renowned industry expert Dr. Sarah Thompson, a leader in testing methodologies, has emphasized, “Custom test fixtures not only enhance the accuracy of test results but also streamline the testing process, allowing for faster product development cycles.” This insight highlights the integral role that these specialized tools play in both improving the reliability of testing outcomes and expediting time-to-market.

Custom test fixtures are designed to meet the unique requirements of various products, providing tailored solutions that generic testing setups cannot offer. By ensuring that products are tested in environments that closely mimic real-world conditions, these fixtures contribute significantly to the overall quality and performance validation of new technologies. As the demand for high-quality and reliable products continues to escalate across industries, investing in custom test fixtures has become a pivotal strategy for companies aiming to maintain a competitive edge. Thus, understanding the best options available for custom test fixtures can significantly enhance testing efficiency and accuracy, ensuring that only the highest standards are met.

Understanding the Importance of Custom Test Fixtures in Software Testing

Custom test fixtures play a crucial role in enhancing software testing efficiency and accuracy. By tailoring test environments and tools to specific project requirements, developers can create more reliable and effective testing processes. These fixtures allow for repetitive and consistent execution of test cases, which helps detect bugs and issues early in the development cycle. The ability to simulate various conditions and inputs ensures that the software behaves as expected under different scenarios, which is vital for maintaining high-quality standards.

Moreover, the importance of custom test fixtures extends beyond just improving accuracy; they also streamline the testing workflow. By automating setups and teardowns, these fixtures minimize the manual effort required, thereby freeing up time for testers to focus on deeper analysis and exploratory testing. This not only accelerates the testing process but also enhances collaboration within teams, as everyone can work from a consistent and reliable foundation. In summary, investing in custom test fixtures is essential for achieving optimal software quality and operational effectiveness.

Types of Custom Test Fixtures and Their Specific Use Cases

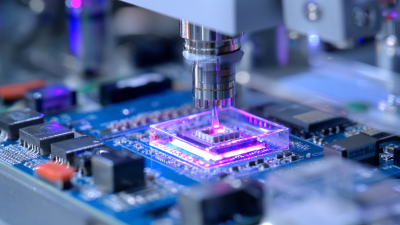

Custom test fixtures play a crucial role in enhancing testing efficiency and accuracy across various industries. These fixtures are specifically designed to hold and test components under specific conditions, ensuring that the testing process is both reliable and repeatable. One common type of custom test fixture is the mechanical fixture, used for physically supporting parts while conducting performance tests. These fixtures can be tailored to accommodate different shapes and sizes of components, making them ideal for applications in automotive and aerospace testing.

Another prevalent use of custom test fixtures is in electrical testing, where fixtures equipped with connectors and measurement devices are designed to assess the electrical characteristics of components such as circuit boards or sensors. These fixtures allow engineers to simulate real-world conditions, ensuring that products meet required specifications before they hit the market. Additionally, thermal test fixtures are used to evaluate a component's behavior under temperature fluctuations, which is crucial in fields like electronics and manufacturing where thermal integrity can impact performance. By utilizing these specialized fixtures, organizations can streamline their testing processes and achieve superior results.

Top Custom Test Fixtures for Enhanced Testing Efficiency and Accuracy

Best Practices for Designing Effective Custom Test Fixtures

When designing effective custom test fixtures, several best practices can significantly enhance testing efficiency and accuracy. According to a report by the International Society for Automation, the implementation of well-designed test fixtures can reduce testing time by up to 40%, allowing for quicker product iterations and time-to-market. A common practice is to ensure that fixtures are modular and adaptable to different testing scenarios. This flexibility not only saves costs but also improves reusability across various projects, leading to improved operational efficiencies.

Another critical aspect is the integration of automation in the design of these fixtures. Automated test fixtures can minimize human error and ensure consistency in results. Studies have shown that automated testing setups can lead to a 30% increase in defect detection rates compared to manual testing approaches. Additionally, using data analytics to inform fixture design can lead to better-targeted test criteria, which further optimizes testing processes.

Tip: Incorporate feedback loops during the design phase; engaging engineers in iterative testing can unveil potential issues early in the process.

Tip: Prioritize ergonomics in fixture design to minimize strain on operators, which not only fosters a better working environment but can also lead to increased productivity. By ensuring ease of use and comfort, you promote a culture of thoroughness in testing.

Integrating Custom Test Fixtures into Test Automation Frameworks

Integrating custom test fixtures into test automation frameworks can significantly enhance both testing efficiency and accuracy. Custom test fixtures are specifically designed setups that replicate the necessary environment and conditions required to conduct thorough tests. By implementing these fixtures within automation frameworks, teams can streamline their testing processes, ensuring that tests are reproducible and reliable. This integration allows for quick adjustments in the testing environment, accommodating various scenarios without extensive manual intervention.

Furthermore, the use of custom test fixtures facilitates better collaboration between development and testing teams. By clearly defining the testing environment and parameters upfront, teams can work more cohesively, reducing the instances of miscommunication and improving overall project timelines. Through automation, the execution of tests becomes a seamless part of the development pipeline, enabling immediate feedback and quicker detection of issues. As a result, integrating custom test fixtures into automation frameworks not only increases the accuracy of testing outcomes but also drives a culture of continuous improvement within the development lifecycle.

Measuring the Impact of Custom Test Fixtures on Testing Outcomes

Custom test fixtures play a pivotal role in enhancing testing efficiency and accuracy across various industries. According to a report from the National Institute of Standards and Technology (NIST), organizations that implement custom test fixtures experience a 20% reduction in testing cycle times. This improvement is primarily attributed to the tailored design of these fixtures, which ensures that tests are conducted under optimized conditions, thereby minimizing variables that could skew results. In industries where precision is paramount, such as aerospace and pharmaceuticals, the impact of custom fixtures cannot be overstated. A study published in the Journal of Testing and Evaluation noted that proper fixture design can lead to a 30% increase in overall test reliability, significantly influencing final product quality.

Moreover, custom test fixtures help standardize testing procedures, leading to more consistent outcomes. The TechAmerica Foundation highlights that organizations utilizing standardized testing processes report a 15% decrease in the incidence of test failures. This consistency is crucial, especially in industries where compliance with regulatory standards is required. By reducing variability in testing setups, custom fixtures not only heighten accuracy but also enhance the repeatability of tests, effectively ensuring that products meet stringent quality benchmarks. Ultimately, the strategic use of custom test fixtures serves as a catalyst for improved testing outcomes, fostering innovation and ensuring that high standards are consistently met across the board.

Related Posts

-

How to Optimize Your Bed of Nails Test Fixture for Maximum Efficiency

-

Exploring Semiconductor Test Socket Innovations at the 138th Canton Fair 2025

-

Understanding Custom Test Fixtures in Software Development Best Practices

-

Exploring IV Curve Tracers: Innovative Applications and Industry Case Studies

-

Understanding the Importance of Custom Test Fixtures in Product Development

-

The Ultimate Guide to Selecting the Right Semiconductor Test Socket for Your Needs