Essential Tips for Designing Custom Test Fixtures for Maximum Efficiency

In today’s fast-paced development environment, the importance of efficient testing cannot be overstated. As industries continue to advance, the complexity of products increases, making the role of custom test fixtures vital in ensuring reliability and performance. Custom test fixtures are tailored solutions that facilitate the testing process, allowing engineers to achieve maximum efficiency. Designing these fixtures involves careful consideration of the specific needs of the project, which can significantly impact the speed and accuracy of testing.

When approaching the design of custom test fixtures, one must focus on elements such as functionality, adaptability, and ease of use. A well-designed fixture not only streamlines the testing process but also minimizes the potential for errors, enabling teams to concentrate on innovation rather than troubleshooting. Moreover, the use of advanced materials and technologies can further enhance the effectiveness of these fixtures, fostering an environment where rigorous testing can be carried out effortlessly.

In this article, we will explore essential tips for creating custom test fixtures that meet the demands of modern testing environments. By understanding the principles of effective design and implementation, engineers and designers can significantly improve testing workflows, ultimately contributing to the success of their projects.

What Are Custom Test Fixtures and Their Importance in Testing?

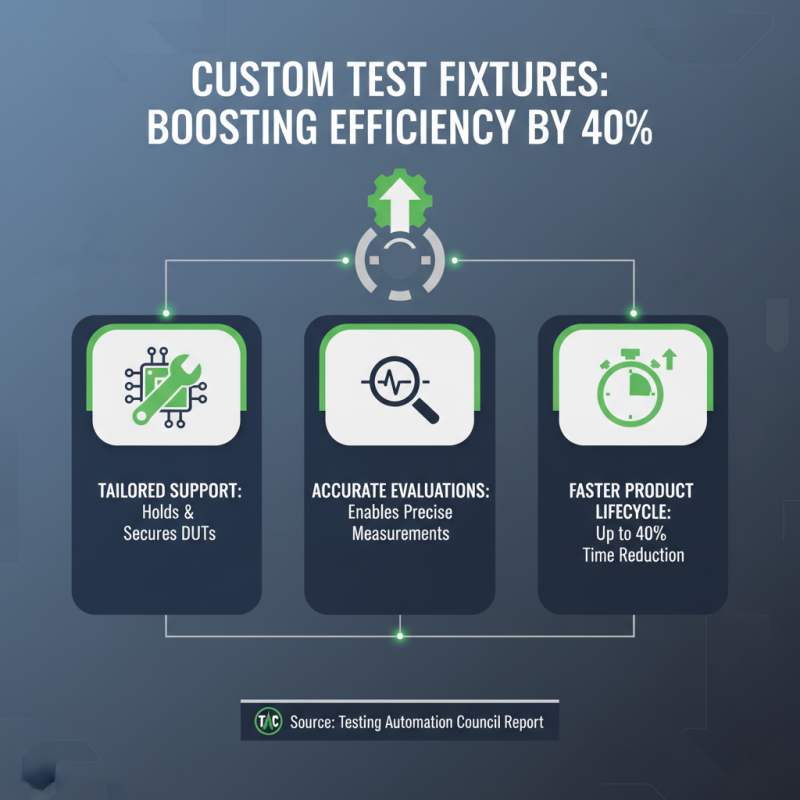

Custom test fixtures are integral components of the testing process, designed to hold and support devices under test (DUTs) while also enabling accurate measurements and evaluations. These fixtures are tailored to specific testing needs, which can significantly enhance efficiency in the development and production phases. According to a recent report from the Testing Automation Council, integrating custom test fixtures can improve testing efficiency by up to 40%, reducing the time required to validate products and accelerating the overall product lifecycle.

The importance of custom test fixtures lies not only in their ability to streamline the testing process but also in their role in maintaining consistency and repeatability in test results. A study conducted by the International Society for Automation indicates that the standardization provided by custom fixtures can lead to a 25% reduction in variability in test outcomes, ensuring that products meet stringent quality standards. Moreover, as industries increasingly lean toward automation and precision, the demand for customized solutions that align with operational workflows continues to grow, highlighting the crucial function of bespoke test fixtures in modern testing environments.

Key Principles for Designing Effective Test Fixtures

When designing effective test fixtures, the most critical principle is ensuring alignment with specific testing requirements. Begin by clearly defining the goals of the test and understanding the components being measured. This clarity will guide the design process and inform decisions around dimensions, materials, and functionalities needed in the fixture. A well-aligned fixture not only improves measurement accuracy but also enhances repeatability, which is vital for consistent testing outcomes.

Another key principle to consider is the ease of use and accessibility of the fixture. The design should facilitate quick setup and teardown to streamline the testing process. Incorporating user-friendly features, such as clear labeling and intuitive interfaces, can significantly reduce the potential for errors during equipment handling. Additionally, ensuring the fixture is robust enough to withstand repeated use without loss of performance is essential to maintain efficiency over time. By focusing on these principles, designers can create test fixtures that not only meet but exceed operational efficiency, ultimately leading to improved testing processes.

Steps for Analyzing Test Requirements and Objectives

Analyzing test requirements and objectives is a crucial step in the design of custom test fixtures. It begins with a thorough understanding of the overall goals of the testing process. Stakeholders should define the specific outcomes they expect from the tests and the criteria that will determine success. This clarity helps in gathering necessary data and creating a detailed list of requirements that the test fixtures must meet.

Once the objectives are clear, it is important to identify the various conditions under which the tests will be conducted. Factors such as operational environment, equipment compatibility, and user interactions should be considered. By understanding these nuances, designers can ensure that the test fixtures are not only suitable for current needs but also flexible enough to accommodate future testing scenarios. This comprehensive analysis serves as the foundation for developing efficient, reliable, and effective test fixtures that can adapt as testing objectives evolve.

Essential Tips for Designing Custom Test Fixtures for Maximum Efficiency

| Test Requirement | Objective | Fixtures Design Consideration | Efficiency Metric |

|---|---|---|---|

| Durability Testing | Ensure product can withstand stress | Materials used should mimic real-world conditions | Lifecycle hours achieved |

| Functional Testing | Validate functionality under normal conditions | Easy adjustments for various configurations | Pass/fail rate |

| Safety Testing | Identify potential hazards | Include sensors and emergency shut-off | Incident reports |

| Usability Testing | Assess ease of use for end users | Consider ergonomic design and accessibility | User satisfaction score |

| Performance Testing | Measure speed and efficiency under load | Ensure proper load distribution in fixture | Response times |

Best Practices for Selecting Materials and Components

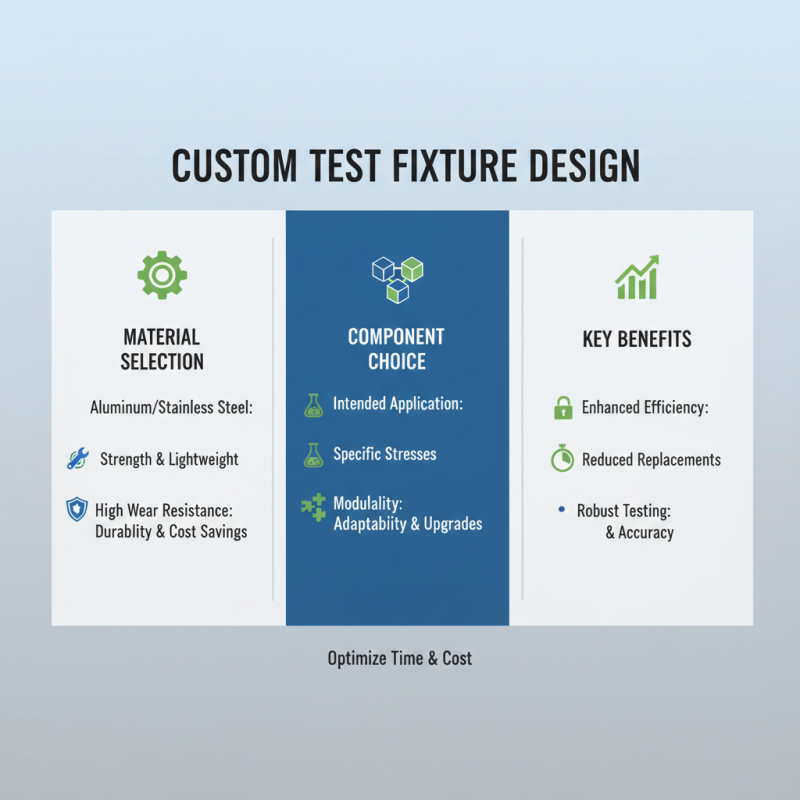

When designing custom test fixtures, selecting the right materials and components is crucial for enhancing efficiency and ensuring robustness in testing scenarios. One of the best practices is to consider the intended application and the specific stresses that the fixture will undergo. For instance, materials like aluminum or stainless steel are often favored for their strength and lightweight properties. Additionally, durability is key; using materials with high resistance to wear and tear can reduce the frequency of replacements, thereby optimizing both time and cost in the long run.

Furthermore, the choice of components should align closely with the fixture's functional requirements. For mechanical parts such as clamps or mounts, precision-engineered components can offer tighter tolerances and improved repeatability. It's also important to assess compatibility between different materials to prevent issues like corrosion, which can arise when metals are paired with certain plastics. By carefully evaluating the properties of each material and component, designers can create test fixtures that not only perform effectively but also stand the test of time, providing reliable results across numerous testing cycles.

Techniques for Testing and Validating Fixture Performance

When designing custom test fixtures, it's crucial to employ techniques that ensure thorough testing and validation of fixture performance. Begin by understanding the specific requirements of the components being tested. This involves outlining the parameters and constraints under which the fixture will operate, which directly impacts its design and functionality. Engaging in detailed discussions with stakeholders can provide insights into potential performance issues and requirements that should be addressed.

Tips for validating fixture performance include the use of simulation software to model the fixture's behavior under various conditions. This approach allows engineers to identify potential faults or inefficiencies before physical prototypes are built, saving both time and resources. Another essential technique is the implementation of iterative testing, where the fixture is continually assessed and refined based on feedback from testing sessions. This iterative process encourages the incorporation of real-world testing scenarios, ensuring that the final design is robust and reliable.

Lastly, consider establishing clear metrics for performance evaluation. Define what constitutes success for the fixture and utilize these benchmarks during testing processes. This not only helps in verifying that the fixture meets its intended use but also fosters a culture of continuous improvement, where adjustments can be made based on empirical data. By focusing on these techniques, designers can enhance the overall efficiency of custom test fixtures, ultimately leading to better quality control and product reliability.

Related Posts

-

How to Optimize Your Bed of Nails Test Fixture for Maximum Efficiency

-

Top Custom Test Fixtures for Enhanced Testing Efficiency and Accuracy

-

Exploring the Versatility of Pogo Pin Receptacles for Modern Electronic Designs

-

How to Enhance PCB Testing Efficiency with Custom Test Fixtures

-

The Ultimate Guide to PCBA Testing Techniques Insights and Best Practices

-

Top 2025 Trends in PCBA Testing: Innovations and Techniques You Can't Miss