How to Effectively Conduct PCBA Testing for Quality Assurance

In the ever-evolving landscape of electronics manufacturing, ensuring the quality and reliability of printed circuit board assemblies (PCBA) is paramount. According to renowned industry expert Dr. Jane Foster, an engineer with over 20 years of experience in PCBA testing, "The robustness of a product is directly tied to the thoroughness of its testing processes." This highlights the critical role that effective PCBA testing plays in quality assurance, ultimately influencing not only production efficiency but also customer satisfaction and product longevity.

Conducting comprehensive PCBA testing involves a strategic approach that encompasses various methodologies—including functional testing, in-circuit testing, and automated optical inspection. Each of these techniques contributes to identifying potential defects early in the manufacturing process, thereby reducing the risk of costly recalls and ensuring that only the highest quality products reach the market. As the complexity of electronic devices continues to increase, the demand for innovative testing solutions has never been greater.

In conclusion, professionals in the field must prioritize rigorous PCBA testing protocols to meet the demands of both the industry and consumers. By adopting best practices in testing, manufacturers not only enhance their products' reliability but also strengthen their market position, ultimately leading to improved business outcomes.

Understanding PCBA Testing and Its Importance in Quality Assurance

Understanding the significance of Printed Circuit Board Assembly (PCBA) testing is essential for ensuring the reliability and performance of electronic devices. As reported by Industry Week, approximately 70% of defects in electronic manufacturing stem from issues in the PCBA phase. This statistic highlights the critical role that thorough testing plays in identifying and mitigating potential failures early in the production process. By implementing rigorous PCBA testing protocols, manufacturers can enhance product quality and reduce the risk of malfunctions in the field.

PCBA testing encompasses a range of methods, including Automated Optical Inspection (AOI), X-ray inspection, and In-Circuit Testing (ICT). According to a study by IPC, companies that adopt comprehensive testing strategies can achieve a 30% reduction in warranty claims and a 25% decrease in return rates. These metrics underscore the financial and reputational benefits of investing in quality assurance measures. Effective PCBA testing not only boosts consumer confidence but also supports manufacturers in maintaining compliance with stringent industry standards, ensuring a competitive edge in the ever-evolving electronics market.

PCBA Testing Results for Quality Assurance

Different Types of PCBA Testing Methods and Their Applications

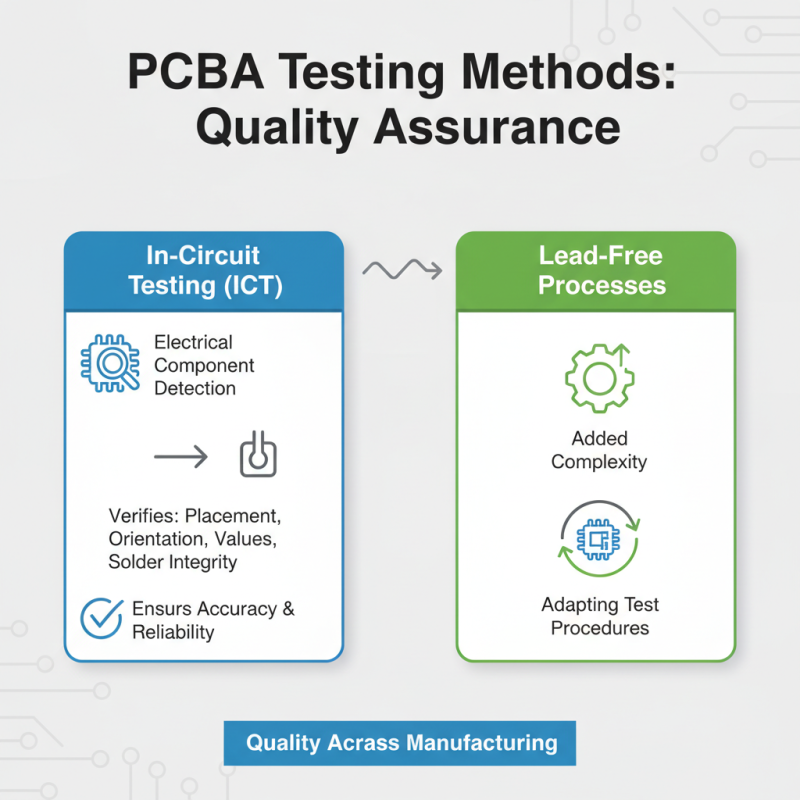

In the realm of printed circuit board assembly (PCBA) testing, various methods play crucial roles in ensuring quality assurance across different manufacturing processes. One widely utilized technique is In-Circuit Testing (ICT), which primarily focuses on the electrical detection of components on a PCB. By verifying component placement, orientation, values, and solder integrity, ICT helps manufacturers ensure the accuracy and reliability of their products. The incorporation of lead-free PCB surface treatment processes further adds a layer of complexity, demanding that existing testing procedures adapt to maintain efficacy.

Another emerging trend is the integration of artificial intelligence (AI) in PCB testing, notably seen with advanced inspection technologies. These AI-driven systems leverage machine learning algorithms to enhance defect detection during the quality assurance phase, significantly increasing both precision and throughput. As the electronics industry continues to evolve, the application of different PCBA testing methods will be pivotal in meeting the growing demand for smaller, more efficient, and reliable electronic devices while addressing challenges such as miniaturization and the need for robust quality control.

Establishing a Comprehensive Testing Protocol for PCBA Quality

Establishing a comprehensive testing protocol for printed circuit board assembly (PCBA) quality is crucial for ensuring the reliability and performance of electronic devices. The first step in developing this protocol involves defining the specific requirements and standards that the PCBA must meet. This includes identifying critical components, functional tests, and compliance with industry regulations. By aligning these requirements with customer expectations, manufacturers can create a targeted testing strategy that addresses potential failure modes and enhances overall product quality.

Once the requirements are set, it is essential to implement a multi-tiered testing approach. This could involve initial visual inspections, followed by automated optical inspections (AOI), functional testing, and in-circuit testing (ICT). Each stage serves to uncover different types of defects, from surface-level issues to complex functional failures. Regular review and refinement of the testing protocol, based on feedback and technological advancements, will facilitate continuous improvement. By fostering a culture of quality assurance that involves all stakeholders, from design engineers to production teams, manufacturers can ensure that the final product not only meets the set standards but also exceeds customer expectations.

Best Practices for Analyzing PCBA Test Results and Data

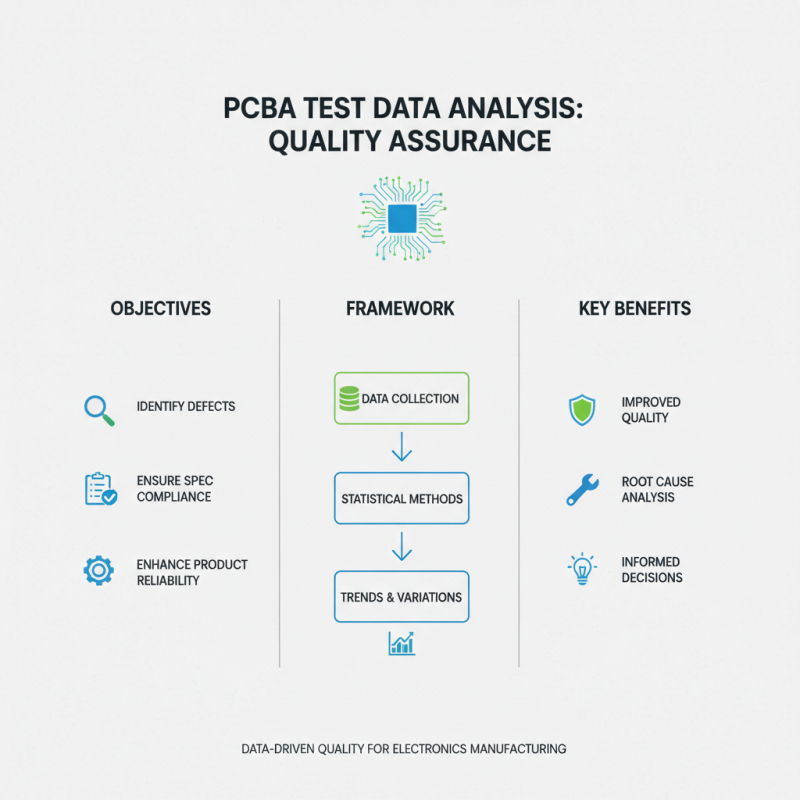

Analyzing PCBA test results is crucial for quality assurance, as it helps to identify defects, ensure compliance with specifications, and enhance overall product reliability. To effectively interpret these results, it’s vital to establish a robust framework for data analysis. Utilizing statistical methods can aid in detecting trends and variations in the test results, allowing engineers to pinpoint areas that require attention.

**Tip:** Always implement control charts during the testing process to monitor variations over time, as this can provide valuable insights into manufacturing consistency.

Additionally, categorize the test results into pass and fail metrics, while maintaining a detailed log of any discrepancies. By analyzing failed tests closely, you can uncover root causes and implement corrective actions. Engaging in regular review sessions with your team can further foster an environment of continuous improvement, streamlining the testing process.

**Tip:** Consider using software tools that facilitate data visualization, as these can enhance your ability to communicate findings effectively to stakeholders.

Common Challenges in PCBA Testing and How to Overcome Them

Conducting PCBA testing effectively is crucial for ensuring the quality and reliability of electronic products. However, several common challenges can arise during the testing process. One significant issue is the complexity of modern PCBAs, which often contain densely packed components. This can make it difficult to access all areas of the board for thorough testing. To overcome this, it’s essential to utilize automated optical inspection (AOI) systems, which can quickly identify defects without manual intervention.

Another challenge in PCBA testing is the potential for false positives or negatives when using traditional testing methods. Inconsistent test results can lead to unnecessary rework or overlooked issues. Implementing consistent testing protocols and utilizing advanced testing equipment, such as X-ray inspection or functional testing, can help mitigate these risks.

**Tip:** Always ensure that your testing equipment is calibrated and maintained regularly to guarantee accurate results.

Additionally, training your testing personnel on the latest techniques and technologies can significantly reduce human error and improve overall testing efficiency.

**Tip:** Develop a comprehensive training program that includes hands-on practice with the equipment to enhance your team's proficiency and confidence in conducting tests.

How to Effectively Conduct PCBA Testing for Quality Assurance - Common Challenges in PCBA Testing and How to Overcome Them

| Challenge | Description | Solution |

|---|---|---|

| Inadequate Test Coverage | Some critical components may not be tested due to limited test points. | Implement a comprehensive test strategy to ensure all components are included. |

| False Positives | Tests may indicate a failure when there is none, wasting time and resources. | Fine-tune test parameters and validate testing equipment regularly. |

| Long Testing Cycles | Prolonged testing may delay production timelines. | Optimize testing procedures and consider automated testing solutions. |

| Equipment Calibration Issues | Testing equipment that is not properly calibrated can lead to inaccurate results. | Establish a regular calibration schedule for all testing equipment. |

| Knowledge Gaps | Lack of experienced personnel can hinder effective testing. | Invest in training and knowledge-sharing sessions for staff. |

Related Posts

-

The Ultimate Guide to Selecting the Right PCB Test Equipment for Your Needs

-

Exploring Pogo Pin Receptacle Innovations at the 138th Canton Fair 2025

-

2025 Top Insights on PCB Functional Testing for Electronics Reliability

-

Innovative PCBA Testing Solutions Transforming Global Supply Chains

-

Top 5 Semiconductor Curve Tracers You Need for Accurate Testing

-

Tailored Solutions for Optimizing Your In Circuit Tester Performance