Top Methods for Effective PCBA Testing Techniques and Best Practices?

In the world of electronics, PCBA testing is crucial. It ensures the reliability and functionality of products. With the rapid advancement in technology, effective testing techniques are more important than ever. Companies must find the best practices to identify defects early. Often, teams face challenges during the testing phase. These include unexpected failures and time constraints.

Implementing effective PCBA testing techniques can greatly reduce risks. It is important to choose methods that suit specific products. Not all techniques work for every situation. This can lead to oversights and failures down the line. For instance, some methods may not detect all types of defects. Moreover, the cost of testing is also a concern. A balance must be struck between thorough testing and budget constraints.

Focusing on continuous improvement in PCBA testing can yield significant benefits. Learning from past mistakes is key. Teams should analyze failures to enhance future testing processes. In a fast-paced environment, agility in testing practices is vital. Regular reviews and updates can help maintain high standards. Ultimately, efficient PCBA testing plays a significant role in product success.

Understanding the Importance of PCBA Testing in Electronics Manufacturing

In the world of electronics manufacturing, PCBA testing is crucial. It ensures the reliability and functionality of printed circuit board assemblies. Without proper testing, defects may go unnoticed. This can lead to product failures and costly recalls. Every detail matters. Small errors in components can have a significant impact on overall performance.

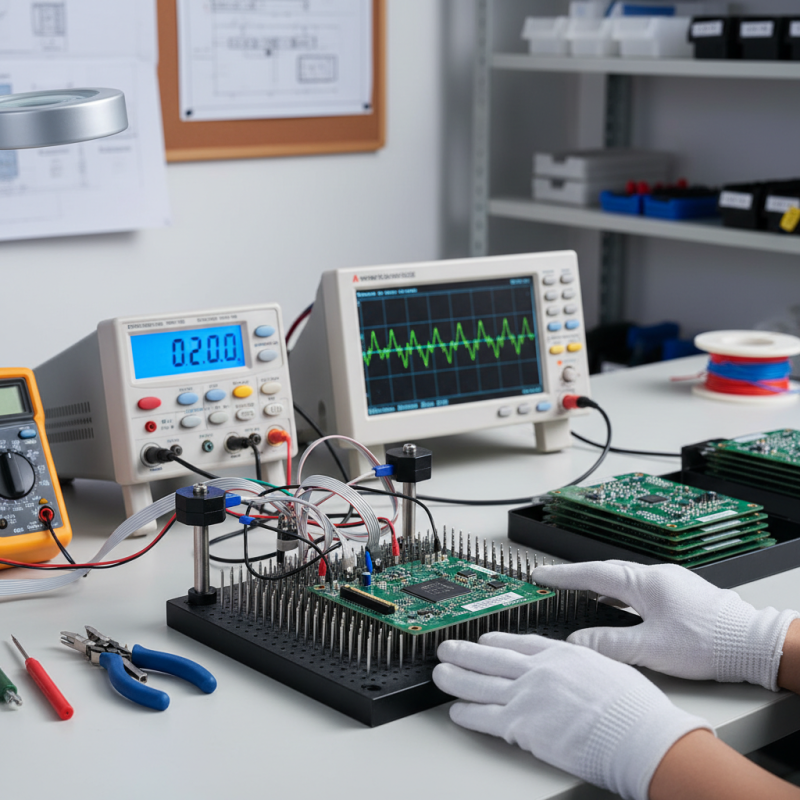

Effective PCBA testing techniques can include visual inspection, automated optical inspection, and functional testing. Each method reveals different types of faults. Yet, relying solely on one technique may not be enough. There can be hidden issues that escape detection. Flexibility in testing approaches is essential. Adapting to specific production requirements is often necessary.

Understanding the importance of these testing practices requires a commitment to quality. Manufacturers should continuously evaluate their testing methods. Some may find their processes lacking. Regular audits and updates can help address weaknesses. Embracing new technologies may also enhance testing efficiency and accuracy. This ongoing journey ultimately leads to improved product confidence in the market.

Key Techniques for Achieving Accurate PCBA Testing Results

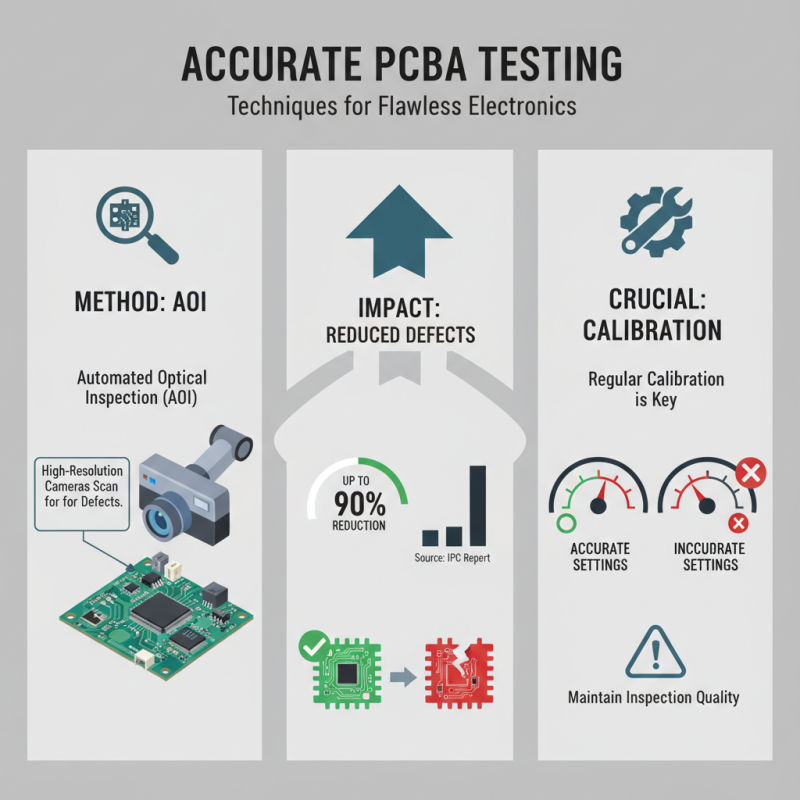

Accurate PCBA testing results hinge on employing the right techniques. One of the key methods is automated optical inspection (AOI). This technique scans the board for defects using high-resolution cameras. According to a report by the IPC, effective AOI can reduce defect rates by up to 90%. Regular calibration is crucial for maintaining inspection quality. Inaccurate settings can lead to missed defects.

Another essential method is in-circuit testing (ICT). It assesses individual components during the assembly phase. The overall effectiveness of ICT can reach over 95% when properly implemented. However, this approach often requires complex fixtures and can be costly. Sometimes, the return on investment may not justify the costs. This reality raises questions about practical implementation.

Functional testing is vital too. It ensures that the assembled PCBA operates as intended. Yet, creating comprehensive test scenarios can be challenging. If scenarios are too simplistic, critical failures might go undetected. An industry study highlighted that nearly 15% of boards fail functional tests due to overlooked parameters. Continuous refinement of test strategies is necessary for achieving reliable results.

Best Practices for PCB Assembly Quality Assurance and Control

Ensuring PCB assembly quality is vital for any electronics project. It directly impacts the performance and reliability of the final product. Start with thorough inspections at every assembly stage. Visual checks should be frequent. Look for misaligned components, soldering issues, or foreign contaminants. Each error can cascade into larger failures down the line.

**Tips**: Conduct random sampling during production. This will help identify issues before they escalate. Testing procedures should include functional tests and in-circuit tests. These checks can reveal problems early. Timely intervention is key.

Documentation is another area that often gets neglected. Keep detailed records of tests and inspections. This can improve traceability and accountability. Review these records regularly to spot trends. Sometimes, recurring issues indicate a deeper problem in the assembly process.

**Tips**: Implement feedback loops with your team. Discuss what went wrong and how to improve. Encourage a culture of quality. It’s essential for long-term success. Adjustments based on firsthand experiences will strengthen your overall QA strategy.

Top Methods for Effective PCBA Testing Techniques and Best Practices

| Testing Method | Description | Advantages | Best Practices |

|---|---|---|---|

| Visual Inspection | Manual or automated inspection of the PCB surface. | Quick detection of obvious defects. | Use adequate lighting; train inspectors properly. |

| Functional Testing | Testing the PCB in a real-world scenario for performance. | Ensures the board meets its intended functionality. | Develop comprehensive test scenarios; simulate operational conditions. |

| In-Circuit Testing (ICT) | Testing individual components while they are on the PCB. | High accuracy in detecting faults; efficient. | Use high-quality probes; maintain test fixtures. |

| Automated Optical Inspection (AOI) | Using cameras and software to inspect PCBs. | Fast and effective for large volumes. | Regularly update inspection algorithms; verify calibration. |

| Boundary Scan Testing | Testing internal connections using JTAG interface. | Effective for complex boards; minimizes test points. | Design for testability; integrate JTAG early. |

Innovative Technologies Enhancing PCBA Testing Processes

Innovative technologies are redefining PCBA testing processes. Automated optical inspection (AOI) systems are a prime example. These systems use high-resolution cameras to detect visual defects on the board. However, they may miss subtle issues, such as those caused by bad soldering. Relying solely on AOI can lead to oversights, making it essential to integrate multiple testing methods.

Another noteworthy advancement is the use of in-circuit testing (ICT). This method checks individual components for functionality. It offers a high level of accuracy but can be costly and time-consuming. Many manufacturers struggle to balance cost and thoroughness. A mix of ICT and other techniques, like functional testing, can enhance the reliability of the testing process.

Lastly, emerging technologies like machine learning are making waves in PCBA testing. Algorithms can predict potential failures by analyzing test data. This adds a predictive aspect, helping in early identification of issues. However, it requires clean data and continual updates to be effective, posing challenges for teams. Exploring these technologies demands careful consideration and reflection on existing practices.

Top Methods for Effective PCBA Testing Techniques

Common Challenges in PCBA Testing and How to Overcome Them

PCBA testing is a critical process, but it can be filled with challenges. One common issue is detecting intermittent faults. These faults may only appear under specific conditions, making them hard to catch. To combat this, engineers should consider using advanced diagnostic equipment. Additionally, creating detailed test conditions can help in identifying these elusive problems.

Another challenge is the inconsistency of test results due to environmental factors. Temperature changes and humidity can affect PCB performance. Regular calibration and maintaining a controlled testing environment are essential. Engineers often overlook this. Simple measures like using dehumidifiers can greatly improve testing results.

Lastly, resources can be limited, leading to rushed testing. This often results in missed faults. Investing time in developing a well-structured testing protocol can streamline the process. Engaging in continuous training for staff also ensures that testing standards are met. Reflection on past testing experiences can reveal areas for improvement.

Related Posts

-

How to Effectively Conduct PCBA Testing for Quality Assurance

-

7 Best Features of Test PCB You Should Know

-

10 Essential Tips for Successful PCB Functional Testing Techniques

-

Top 10 Pin Pogo Sticks: Ultimate Guide to the Best Bouncing Fun!

-

Top 5 Semiconductor Curve Tracers You Need for Accurate Testing

-

Why Choosing the Right PCB Test Jig is Crucial for Your Manufacturing Success