10 Essential Tips for Choosing PCB Test Equipment for Your Projects?

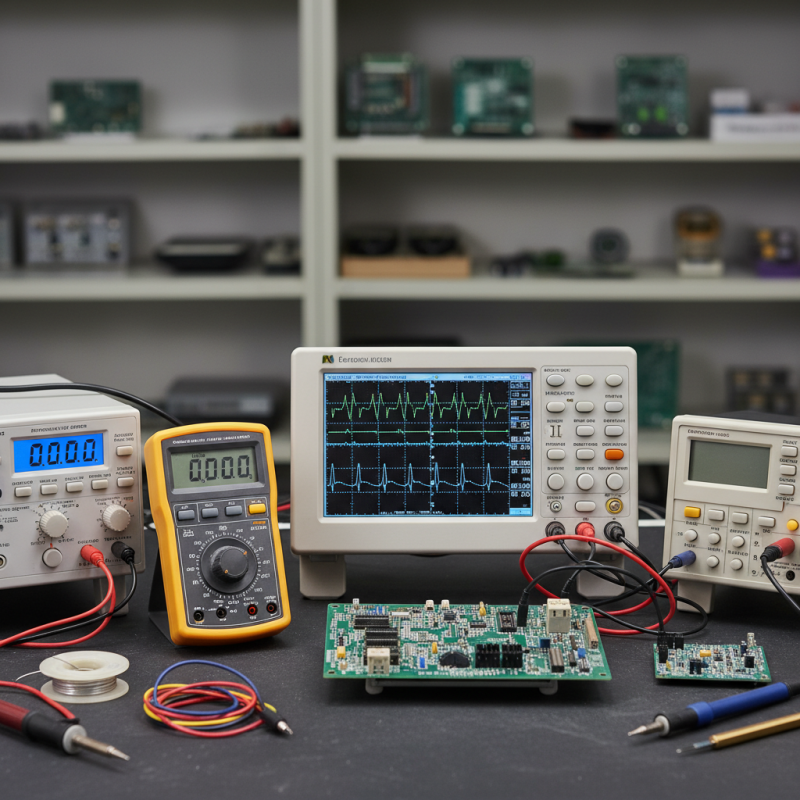

When working on electronic projects, choosing the right pcb test equipment is crucial. This selection can greatly impact the accuracy and efficiency of your testing processes. Various options are available, and understanding their functions is essential for successful project execution.

Selecting suitable pcb test equipment involves several factors. You must consider the specifications required for your specific application. Not all tools suit every project, which may lead to suboptimal results. Pay attention to features like resolution, speed, and compatibility with your components.

It's easy to overlook details in this process. Many users often choose equipment based on brand recognition rather than actual performance. This can result in unexpected challenges during testing. Reflecting on past experiences can help guide your decisions toward more effective tools that truly meet project needs.

Understanding the Types of PCB Test Equipment and Their Applications

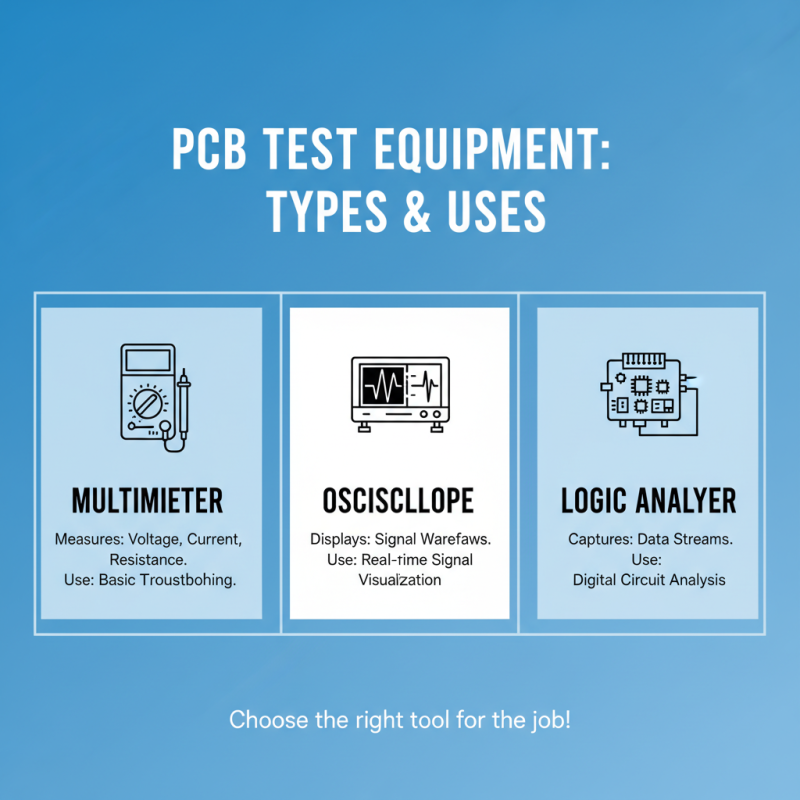

When selecting PCB test equipment, understanding the types available is crucial. Each type serves a specific purpose. For instance, multimeters measure voltage, current, and resistance. They are essential for basic troubleshooting. Oscilloscopes display signal waveforms. They help visualize electrical signals in real-time. Logic analyzers are key for digital circuits. They capture and analyze complicated data streams.

Another common type is the network analyzer. These tools assess the performance of RF circuits. They can be complex but invaluable for high-frequency designs. Automated test equipment (ATE) is another option. It can run tests on multiple boards simultaneously. This can save time. However, it requires a steep learning curve and setup.

Choosing the right equipment may feel overwhelming. Each project may have unique needs. It's important to reflect on the project's requirements. Sometimes, simpler tools yield better results than advanced options. Testing methods may not work as intended without careful calibration. Unpacking all these aspects can help in making a more informed choice.

Key Specifications to Consider When Selecting PCB Test Instruments

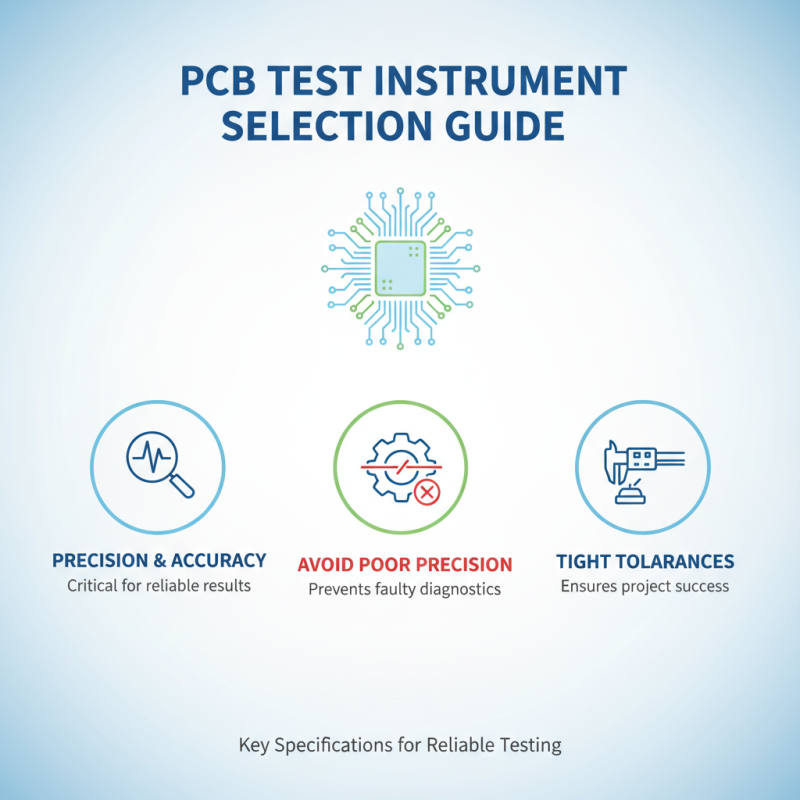

When selecting PCB test instruments, paying attention to key specifications is crucial for project success. Look for equipment that offers precision and accuracy. These factors can significantly impact the results of your tests. Poor precision may lead to faulty circuitry or incorrect diagnostics. Always prioritize devices with tight tolerances.

Tip: Consider the testing environment. Some instruments may not function well in extreme conditions. Think about your workspace's temperature and humidity. If your tests will occur outside these ranges, factor that into your selection. Equipment that can adapt is invaluable.

Another important specification is the versatility of the test instrument. A tool that can perform multiple tests is practical. It saves time and space in your lab. However, sometimes multifunctional devices can lack depth in specific tests. This could lead to oversights in your PCB performance evaluation, which is where a single-function device might be preferable. It's essential to weigh this balance carefully.

Evaluating Accuracy and Resolution in PCB Testing Equipment

When selecting PCB test equipment, accuracy and resolution are critical factors. Accuracy refers to how close a measurement is to the true value. Resolution, on the other hand, is the smallest change that can be detected by the equipment. Many users overlook these aspects, leading to frustrating outcomes in their projects. A small error can have significant impacts on the functionality of a PCB.

Choosing equipment with high accuracy can improve your test results. Look for devices that specify their accuracy levels. A range of ±1% might be acceptable for some projects, but others may require higher precision. It's also important to consider the resolution. For example, a multimeter that can measure to the hundredth of a volt might be ideal for sensitive applications. Keep in mind, though, that higher resolution can result in longer processing times.

Remember to assess your project's specific needs. Is the equipment easy to use? Does it require training? These questions help you avoid pitfalls. Additionally, think about the environment. Test equipment may perform differently at varying temperatures or humidity levels. Balancing accuracy and practicality can be challenging, yet it is essential for successful PCB testing.

Cost-Effectiveness Analysis of PCB Testing Solutions for Projects

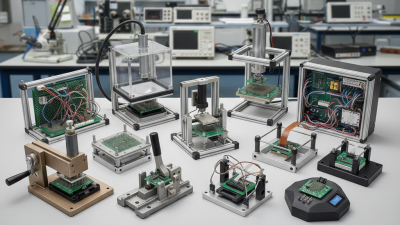

When selecting PCB test equipment, cost-effectiveness is crucial. Quality testing solutions can be expensive. However, investing in the right tools can save money in the long run. Consider how often you will use the equipment. If it’s a one-time project, renting may be a better option. Analyze the costs of both buying and renting before making a decision.

Evaluate the features offered by different testing solutions. Look beyond the price tag. Some cheaper options may lack essential functionalities. This could lead to increased costs later. A device that can perform multiple tests may be more economical. Furthermore, think about the support and training that may come with your purchase. Free resources can enhance the overall cost-effectiveness of your choice.

Another aspect to reflect on is the potential for repairs and maintenance. Some cheaper devices may require more frequent servicing. This can add unexpected costs. Ensure you factor in these elements when making your decision. Choosing wisely can significantly impact your project’s budget. However, it’s easy to overlook these details in the excitement of selecting new equipment.

Industry Standards and Compliance Requirements for PCB Test Equipment

When selecting PCB test equipment, industry standards and compliance are critical. A 2022 report from IPC reveals that 78% of manufacturers prioritize compliance when choosing testing tools. This highlights the importance of adhering to established guidelines. Common standards include IPC-A-600 and IPC-2221, which outline acceptable quality and design practices. Testing equipment must meet these criteria to ensure reliability and functionality.

Additionally, certification from recognized organizations can add value. Test equipment that complies with ISO 9001 standards often brings assurance of consistent quality. This compliance helps in minimizing rework and warranty claims. However, many companies overlook the need for regular calibration and maintenance, leading to inaccurate results.

Furthermore, understanding environmental regulations is essential. RoHS compliance, for instance, limits hazardous substances in electronic products. Neglecting these regulations can result in costly penalties and project delays. Investing in compliant testing equipment not only meets standards but can enhance overall project efficiency. Choosing tools with built-in features for regulatory testing can simplify processes, yet requires upfront research and evaluation. Continual assessment of equipment and processes can prevent costly oversights.

10 Essential Tips for Choosing PCB Test Equipment

Related Posts

-

The Ultimate Guide to Selecting the Right PCB Test Equipment for Your Needs

-

The Evolution of PCB Test Fixtures Shaping the Future of Electronics Manufacturing

-

Top 10 PCB Test Jigs You Need for Perfect Testing?

-

What is Pin Pogo? Exploring Its Features, Benefits, and Uses in 2023

-

How to Choose the Right PCB Functional Testing Methods for Your Production Needs

-

5 Innovative PCB Test Fixture Solutions for Efficient Circuit Board Testing