How to Optimize Wafer Testing for Enhanced Semiconductor Performance

In the rapidly evolving semiconductor industry, optimizing wafer testing is crucial for ensuring superior device performance and reliability. Renowned industry expert Dr. Jane Smith, a leading figure in semiconductor research, emphasizes that "effective wafer testing is the cornerstone of high-performing semiconductor chips." This sentiment encapsulates the foundational role that precise and efficient testing processes play in the development of cutting-edge technologies.

Wafer testing not only determines the quality of semiconductor wafers but also influences yield rates and production efficiency. As the demand for smaller, faster, and more efficient electronic devices grows, the pressure on manufacturers to refine their testing methodologies intensifies. By adopting advanced techniques and leveraging innovative tools, the semiconductor industry can enhance wafer testing protocols, thus improving overall performance metrics.

In this article, we will explore various strategies and technologies that can optimize wafer testing procedures. From utilizing automated testing systems to integrating machine learning algorithms for predictive analysis, these enhancements are instrumental in meeting the challenges posed by next-generation semiconductor applications. Through a comprehensive approach to wafer testing, manufacturers can significantly elevate the performance standards for semiconductor devices, ensuring they remain competitive in a global marketplace.

Understanding Wafer Testing and Its Importance in Semiconductor Performance

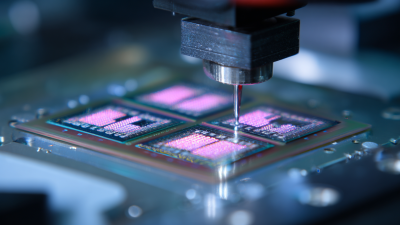

Wafer testing is a critical process in semiconductor manufacturing that directly impacts the performance and reliability of integrated circuits. By evaluating the electrical characteristics of semiconductor wafers, manufacturers can identify defects and assess the functionality of individual chips before they are packaged. This testing process not only ensures that only high-quality wafers proceed to the next stages of production but also minimizes costly failures in the final products. Understanding the significance of this step helps engineers and manufacturers implement more effective testing strategies to enhance overall yield and performance.

The importance of wafer testing extends beyond immediate defect detection. It provides valuable data for process improvements and design adjustments, enabling manufacturers to optimize their fabrication techniques. By analyzing the outcomes of wafer tests, manufacturers can make informed decisions on process parameters and materials, ultimately resulting in better semiconductor performance. Furthermore, as technology advances and devices become smaller and more complex, the challenges associated with wafer testing continue to grow, underscoring the necessity for innovation in testing methodologies to keep pace with the rapid evolution of the semiconductor industry.

Key Factors Affecting Wafer Testing Efficiency and Accuracy

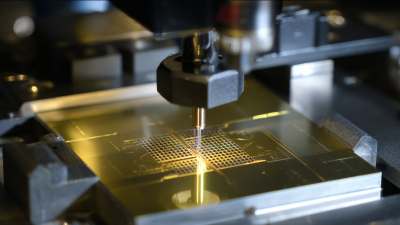

Wafer testing is a critical step in the semiconductor manufacturing process, where efficiency and accuracy can significantly affect overall performance. One of the primary factors affecting testing efficiency is the optimization of testing equipment. Advanced testing tools, capable of high-speed data acquisition and processing, can reduce the time spent on each wafer while maintaining rigorous quality standards. Moreover, implementing automation in testing procedures allows for consistent throughput, minimizing human error and increasing reliability in results.

Another key factor influencing wafer testing accuracy is the calibration of testing parameters. Ensuring that the equipment is properly calibrated to account for variations in wafer thickness, material properties, and environmental conditions plays a crucial role in achieving accurate measurements. Furthermore, the integration of advanced algorithms and data analytics can enhance defect detection, helping to identify anomalies that might otherwise go unnoticed. By focusing on these critical aspects, companies can improve the overall effectiveness of their wafer testing processes, leading to better semiconductor performance and reduced production costs.

Techniques to Enhance Wafer Testing Processes and Methodologies

Optimizing wafer testing is crucial for enhancing semiconductor performance, particularly as the industry moves towards more complex and miniaturized devices. By improving testing processes and methodologies, manufacturers can ensure higher yields and better reliability of semiconductor products.

One effective technique is the integration of advanced testing algorithms. These algorithms can analyze data in real-time, allowing for quicker identification of defects and performance issues. Additionally, implementing automated testing systems can reduce human error and increase throughput, ultimately leading to more efficient testing cycles.

Tips: Consider investing in training for your testing teams to ensure they are familiar with the latest technologies and methodologies. Regularly revisiting and updating the testing protocols can also prevent stagnation and provide a competitive edge. Another key aspect is to incorporate feedback loops, where insights from testing outcomes are used to refine the design and production processes continually.

Implementing Advanced Technologies for Optimized Wafer Testing

The optimization of wafer testing is crucial in enhancing semiconductor performance, and implementing advanced technologies plays a pivotal role in this process. One of the most effective approaches is the integration of automated systems that leverage machine learning algorithms. These systems can analyze vast amounts of testing data in real time, identifying patterns and anomalies that may not be apparent through traditional testing methods. By harnessing artificial intelligence, manufacturers can optimize test parameters dynamically, reducing cycle times while improving accuracy in defect detection.

Moreover, the adoption of advanced measurement techniques, such as non-contact optical inspection and high-resolution electrical testing, enhances the reliability of wafer testing processes. These technologies facilitate more detailed assessments of semiconductor devices, allowing for early detection of faults that could lead to performance issues downstream. By implementing robust data analytics, chipmakers can gain deeper insights into their manufacturing processes, making informed decisions about design and production that ultimately boost yield and performance metrics while minimizing waste.

Monitoring and Analyzing Results for Continuous Improvement in Testing

Monitoring and analyzing results is a critical aspect of optimizing wafer testing for enhanced semiconductor performance. By employing advanced data collection techniques, engineers can capture vast amounts of information during testing phases. This data serves as the foundation for identifying performance trends, understanding failure mechanisms, and detecting anomalies in semiconductor devices. Effective monitoring systems utilize real-time analytics to provide immediate feedback, enabling rapid adjustments to testing protocols. This proactive approach minimizes the risk of overlooking critical issues that may affect the overall performance and reliability of semiconductor products.

Continuous improvement in testing hinges on a systematic analysis of the collected data. Implementing statistical process control (SPC) methods can help identify variations in testing outcomes, allowing teams to pinpoint specific areas needing improvement. By establishing key performance indicators (KPIs) and regularly reviewing them, organizations can create a feedback loop that informs ongoing process refinement. This culture of analytics-driven decision-making not only enhances the efficiency of wafer testing but also fosters innovation, ensuring that semiconductor performance consistently meets the evolving demands of the industry.

Related Posts

-

Understanding the Importance of Semiconductor Testing in Modern Technology

-

How to Maximize Efficiency in Wafer Probing Processes with Advanced Techniques

-

Understanding Wafer Probing Techniques for Enhanced Semiconductor Performance

-

How to Choose the Right Pogo Pins for Your PCB Design Needs

-

Solutions for Innovative Pogo Pin Array Applications in Modern Electronics

-

Top 10 Pin Pogo Sticks: Ultimate Guide to the Best Bouncing Fun!