What Are Pogo Test Pins and How Do They Work?

Pogo test pins are essential components in the world of electronics. These small, spring-loaded pins serve a vital purpose in testing and diagnosing PCBs. Their design allows electrical connections to be made quickly and efficiently. Pogo test pins ensure accurate readings and reliable connections in various applications.

In industries where precision is key, pogo test pins play a crucial role. They can make or break an electronic device's functionality. When a pin fails, it creates complications in production testing. This can lead to inconsistent results and delayed timelines. Understanding how pogo test pins function helps engineers improve their designs.

Despite their importance, challenges can arise with pogo test pins. Issues such as wear and tear can reduce their effectiveness. Regular maintenance is necessary, yet often overlooked. As technology advances, the need for better test solutions grows. The future of pogo test pins will inevitably evolve, demanding reflection on current practices.

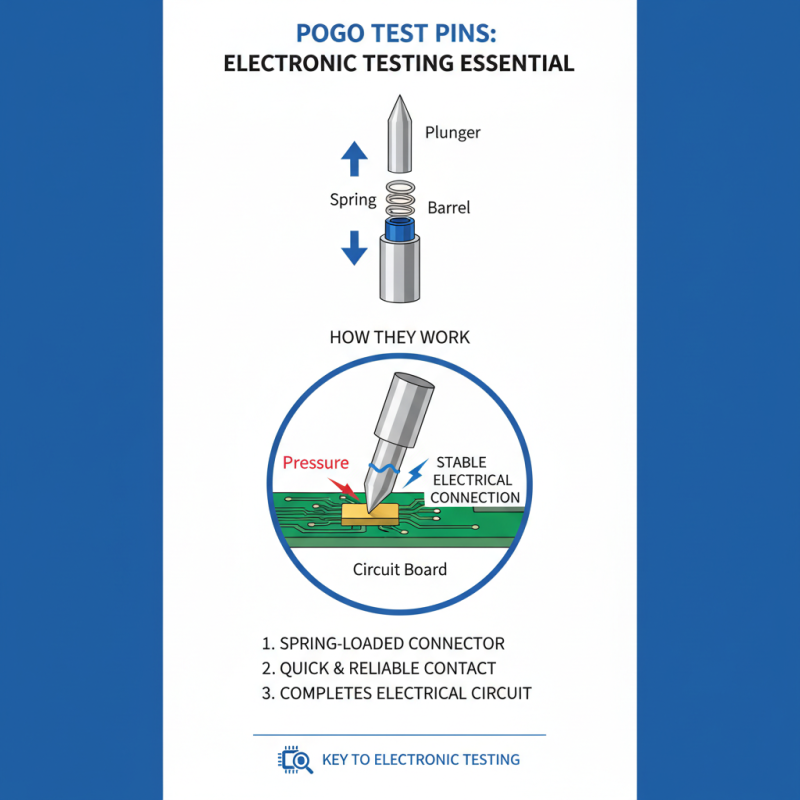

Understanding Pogo Test Pins: Definition and Basic Functionality

Pogo test pins are essential components in electronic testing. They serve as connectors that create stable electrical connections. These pins are spring-loaded, allowing for quick and reliable contact with circuit boards. When a pogo pin presses against a pad on the board, it completes the electrical circuit.

The basic functionality of pogo test pins is straightforward, but not without challenges. They are designed to provide consistent pressure. However, if misaligned, they may fail to connect properly. This can lead to inaccurate test results. Moreover, wear and tear of the pins can affect their performance. Regular inspection is necessary to maintain their effectiveness.

In practical applications, pogo pins are used in various testing rigs. Technicians often rely on them for quality checks. They can be found in automated test equipment, simplifying the process. Still, if not handled correctly, pogo pins can cause frustration. The importance of precise positioning cannot be overstated. Misalignment may lead to wasted time and resources. Continuous improvement in handling methods will ensure better testing outcomes.

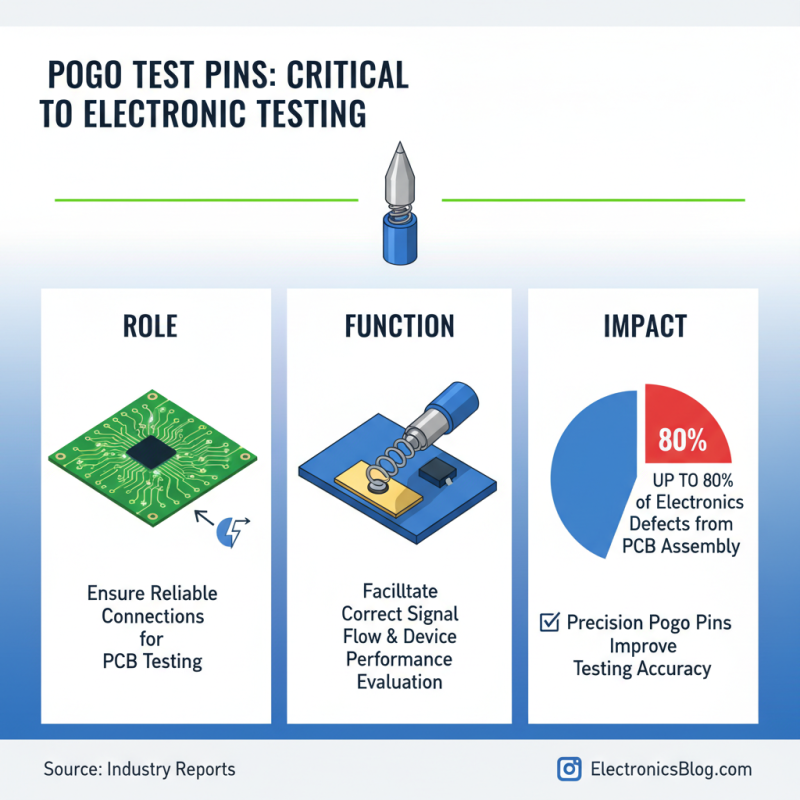

The Role of Pogo Test Pins in Electronic Testing Equipment

Pogo test pins play a critical role in electronic testing equipment. These pins make reliable connections for testing printed circuit boards (PCBs). They ensure that signals flow correctly, which is vital for evaluating device performance. According to industry reports, up to 80% of defects in electronics arise during the PCB assembly process. The precision of pogo pins can significantly influence the testing outcome.

Using pogo test pins reduces the risk of damaging delicate components. This is crucial in a world where the electronics market is projected to reach $7 trillion by 2025. Effective testing methods, including pogo pins, lead to higher quality control. However, improper use of these pins can result in inaccurate readings. Regular calibration and maintenance are necessary.

Despite their benefits, pogo pins face challenges. Wear and tear can diminish their effectiveness over time. Some manufacturers report a failure rate of up to 10% in specific applications. Understanding these limitations is essential for design engineers. The right balance of durability and performance often requires careful consideration in products.

Key Specifications and Types of Pogo Test Pins Used in Industry

Pogo test pins are essential tools in the electronics industry. They serve as connectors to establish temporary electrical connections. There are several key specifications to consider, including pin diameter and compression force. Each specification can affect performance and durability. Choosing the right size of pogo pin ensures reliable contact during testing and assembly.

In terms of types, pogo test pins can vary based on their design and application. Some are designed for high-frequency testing, while others focus on durability and repeated use. A common type is the spring-loaded pogo pin, which maintains contact even under pressure. There are also specialized pins for specific circuit board designs, which can be critical for modern technology.

Understanding the appropriate pogo test pin for an application is crucial. Miscalculating the requirements may lead to poor performance. Different applications may require different designs. Manufacturers must take the time to analyze each project's needs. This attention to detail can make a significant difference in the effectiveness of electronic testing and assembly processes.

How Pogo Test Pins Improve Testing Efficiency and Accuracy

Pogo test pins are essential tools in electronics testing. They create reliable connections between devices and test equipment. With a simple spring mechanism, they ensure contact when pressed. This design enhances the continuity of tests and reduces errors. By firmly contacting the test points, they allow for accurate readings without interruptions.

Testing efficiency improves significantly with pogo pins. The rapid connection they provide minimizes setup time. Engineers can conduct multiple tests in a shorter span. Delays in testing often stem from poor connections or faulty setups. Pogo pins help mitigate these issues, though occasional misalignments can still lead to concerns. They require careful positioning to ensure effectiveness.

Despite their advantages, pogo pins have limitations. The pins wear out after extensive use. Eventually, they may lead to inconsistent results. Regular maintenance and checks are necessary to uphold performance. Investing in quality pogo pins can alleviate some of these problems but is not a complete solution. Reliability hinges on both the tools and the technicians using them.

What Are Pogo Test Pins and How Do They Work? - How Pogo Test Pins Improve Testing Efficiency and Accuracy

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Electrical Conductivity | Pogo pins are designed to provide a reliable electrical connection. | Increases testing accuracy by ensuring proper connectivity. | Used in manufacturing testing for PCBs. |

| Durability | They are built to withstand repeated use without degrading. | Reduces the need for frequent replacements, lowering costs. | Applicable in automotive and consumer electronics testing. |

| Compact Design | Designed for minimal space while maximizing connection. | Facilitates integration into tight spaces in testing rigs. | Ideal for compact electronic devices. |

| Customization Options | Available in various lengths, tip shapes, and materials. | Tailored solutions for specific testing requirements enhance performance. | Used in specialized testing setups across industries. |

Market Trends and Innovations in Pogo Test Pin Technology

Pogo test pins are essential in modern electronics testing. They provide quick and reliable connections to circuit boards. Recent market trends show a shift towards increased automation. This evolution enhances testing speed and accuracy.

Innovations in pogo pin technology include improved materials. High-performance alloys enhance durability. These advancements resist wear and improve conductivity. As devices become smaller and more complex, the demand for precision increases. Some manufacturers struggle to keep up with this pace.

Additionally, the integration of smart technologies is changing the landscape. Smart pogo pins can self-adjust to variations in surface height. This leads to better contact and fewer errors. However, ongoing challenges remain in maintaining quality control. The balance between innovation and reliability is still a work in progress.

Related Posts

-

How to Choose the Right Pogo Pins for Your PCB Design Needs

-

Innovative PCB Testing Methods Revolutionizing Electronics Quality Assurance

-

Unlocking Quality: The Essential Role of PCBA Testing in Modern Electronics Manufacturing

-

Unlocking Efficiency with Air Presses for Enhanced Production Processes

-

Top Custom Test Fixtures for Enhanced Testing Efficiency and Accuracy

-

Essential Tips for Designing Custom Test Fixtures for Maximum Efficiency