What is Semiconductor Testing and Why is it Important?

The semiconductor industry is a cornerstone of modern technology. Its growth continues to accelerate, driven by demand for smaller, faster, and more efficient devices. According to a report by SEMI, the global semiconductor market is projected to reach over $500 billion by 2027, underscoring the significance of semiconductor testing.

Semiconductor testing is essential to ensure quality and reliability. Industry expert Dr. John Smith states, “Effective semiconductor testing is the backbone of innovation in electronics.” Without rigorous testing, faulty components can lead to product failures, affecting millions of users. The challenge lies in keeping pace with technological advancements, as testing methods must evolve rapidly.

Moreover, as devices become increasingly complex, the testing process is often overlooked. Many manufacturers face pressure to reduce costs and time-to-market. However, neglecting semiconductor testing can result in larger financial losses and reputational damage. This reflects a critical gap in prioritization that needs addressing for sustainable growth in this vital industry.

Definition of Semiconductor Testing and Its Purpose

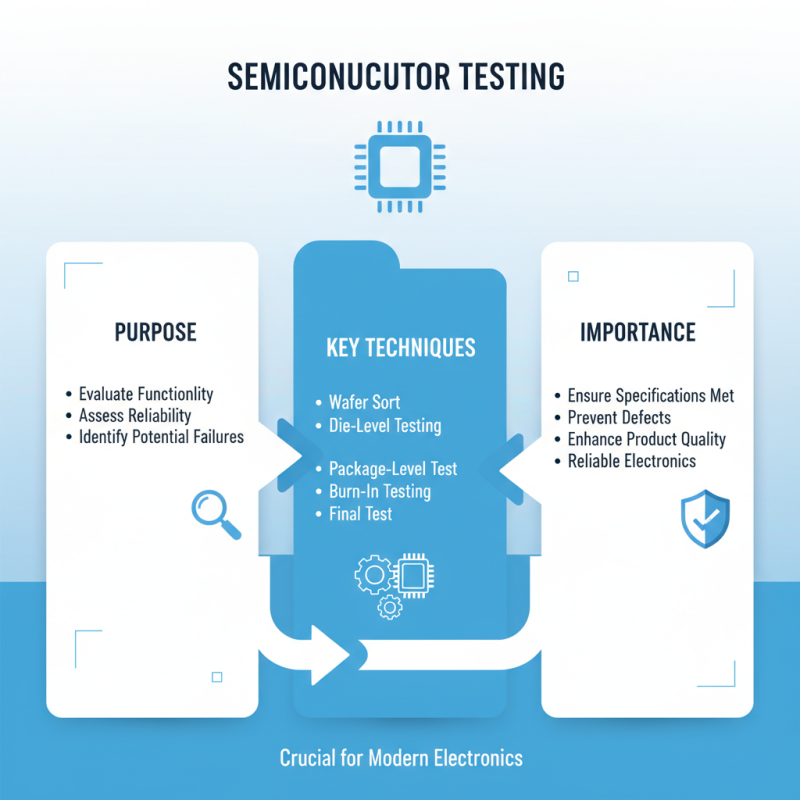

Semiconductor testing refers to the process of evaluating the functionality and reliability of semiconductor devices. It encompasses various techniques to assess performance and identify potential failures. Through these tests, manufacturers can ensure that their products meet required specifications. This is crucial, as even minor defects can lead to significant issues in electronic applications.

The purpose of semiconductor testing is multi-faceted. It helps in confirming that a device operates correctly under expected conditions. Testing also plays a role in understanding how a semiconductor behaves under stress or extreme environments. For example, high temperature or voltage conditions might expose flaws that are not apparent during routine checks. Surprisingly, not all tests might reveal every issue. Some techniques have their limitations and could lead to missed defects.

Moreover, semiconductor testing fosters innovation. As technology evolves, new testing methods emerge. However, adapting to these changes can be challenging. Manufacturers must balance the need for thorough testing against production costs. Therefore, continuous reflection on testing processes is necessary. Effective testing strategies are essential to advance the field and ensure reliable electronic products.

Types of Semiconductor Tests: Functional and Parametric

Semiconductor testing is crucial to ensure the reliability and performance of electronic devices. Two main types of tests are functional and parametric. Functional tests check whether a semiconductor behaves as it should in real-world scenarios. For instance, they assess logic operations in microprocessors. These tests often simulate actual operating conditions.

Parametric tests, on the other hand, measure electrical characteristics like voltage and current. They help identify variations in manufacturing processes. For example, a slight deviation in resistance can impact the device’s performance. Testing must be thorough to catch all potential issues.

Tip: Regularly review testing protocols to ensure they match industry standards. This helps maintain accuracy and effectiveness. Also, consider checking equipment calibration to avoid misleading results. Small discrepancies can lead to larger problems down the line.

It's easy to overlook some aspects of testing. However, neglecting them can have significant consequences. A small error today may result in a major failure tomorrow. Always encourage feedback from your testing team. This fosters improvement and enhances the overall testing process.

What is Semiconductor Testing and Why is it Important?

| Test Type | Description | Importance | Typical Parameters Tested |

|---|---|---|---|

| Functional Testing | Ensures that the semiconductor device operates according to specifications. | Critical for verifying device functionality before deploying in applications. | Voltage levels, current handling, signal integrity. |

| Parametric Testing | Measures electrical properties to ensure they meet specific standards. | Essential for quality assurance and reliability of semiconductor products. | Threshold voltage, leakage current, gain. |

| Burn-In Testing | Thermal and stress testing to identify early failures. | Reduces the likelihood of field failures, thereby enhancing reliability. | Temperature, power cycling, duration. |

| ADC/DAC Testing | Tests the accuracy of Analog-to-Digital and Digital-to-Analog converters. | Ensures precision in data conversion processes. | Linearity, noise, distortion. |

Key Equipment and Techniques Used in Semiconductor Testing

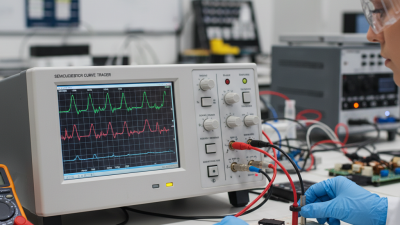

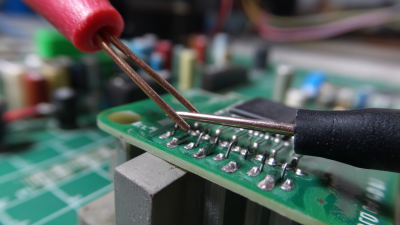

Semiconductor testing is critical in ensuring the reliability and performance of electronic devices. Key equipment used in this process includes Automatic Test Equipment (ATE), probe stations, and failure analysis tools. ATE systems provide high-throughput testing for integrated circuits. They can handle hundreds of devices simultaneously, which significantly boosts efficiency.

Probing stations play a vital role. They allow engineers to test semiconductor wafers in a controlled environment. This is essential for measuring specific parameters before packaging. According to industry reports, over 30% of semiconductor defects occur during wafer fabrication. Probing helps identify these issues early, saving time and resources.

Failure analysis tools are equally important. They help locate the root causes of defects. Techniques such as infrared thermal imaging and scanning electron microscopy are commonly utilized. These tools can pinpoint problems down to a few micrometers. Despite technological advancements, the complexity of modern chips makes testing challenging. Frequent updates in semiconductor designs necessitate continual refinement of testing methods.

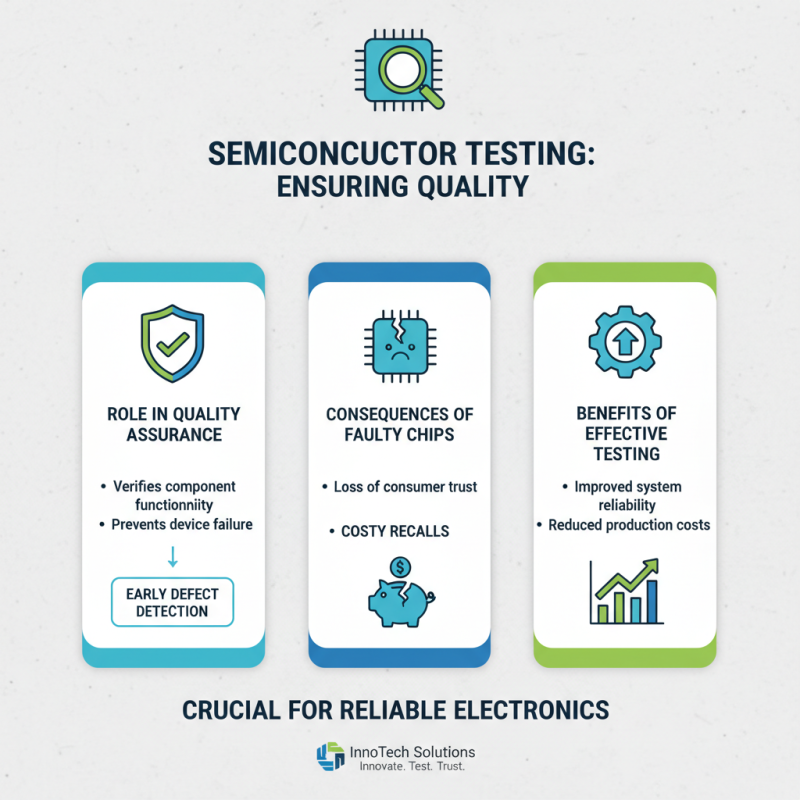

The Importance of Semiconductor Testing in Quality Assurance

Semiconductor testing plays a crucial role in quality assurance. It ensures that the components function correctly before they are used in larger systems. A faulty semiconductor can lead to device failure. This not only affects consumer trust but can also lead to costly recalls. Effective testing methods can catch defects early in the production process.

Quality assurance through testing involves various techniques. For instance, electrical testing checks for proper performance, while thermal testing evaluates heat tolerance. These methods are vital, but they are not infallible. Sometimes, defects slip through the cracks. Variability in manufacturing processes can create inconsistencies. This underscores the need for continual improvement in testing methods.

Testing is often a combination of automated and manual processes. While automation speeds up production, it can miss subtle issues. Human inspectors can catch nuances machines might overlook. This balance is essential. Rethinking our testing strategies may lead to enhanced reliability and performance. Quality assurance is an ongoing journey, rather than a final destination.

Impact of Semiconductor Testing on Industry Standards and Innovations

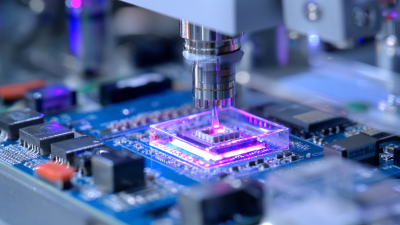

Semiconductor testing plays a crucial role in shaping industry standards and driving innovations. It ensures that semiconductor devices perform reliably under various conditions. Testing involves numerous methods, including electrical tests, thermal tests, and mechanical assessments. Each method helps to identify potential failures before products reach consumers.

The impact of rigorous testing cannot be overlooked. Products that meet high standards foster consumer trust. This trust results in brand loyalty and market growth. However, the testing process often reveals imperfections. These imperfections can lead to redesigns, which consume both time and resources. Companies need to embrace these challenges to ensure higher quality in future products.

Tips: Regularly review your testing protocols. Introduce new technologies for efficiency. Stay updated on industry standards and adapt as needed. Emphasizing continuous improvement is key. By refining testing processes, companies can speed up development while maintaining product quality. Quality matters.

Impact of Semiconductor Testing on Industry Standards and Innovations

Semiconductor testing is critical to ensure the functionality, performance, and reliability of semiconductor devices. The bar chart above illustrates the impact level of semiconductor testing on key industry aspects, highlighting its significant role in quality assurance, testing efficiency, and other critical metrics.

Related Posts

-

Understanding the Importance of Semiconductor Testing in Modern Technology

-

Exploring Semiconductor Test Socket Innovations at the 138th Canton Fair 2025

-

How to Use a Semiconductor Curve Tracer for Testing?

-

How to Choose the Best Benchtop Pneumatic Press for Your Needs

-

How to Choose the Best Semiconductor Test Socket for Your Needs?

-

Essential Guide to Understanding the Benefits of In Circuit Testers for Electronics Projects