Top 10 Pogo Pin Receptacles You Need for Your Electronic Projects

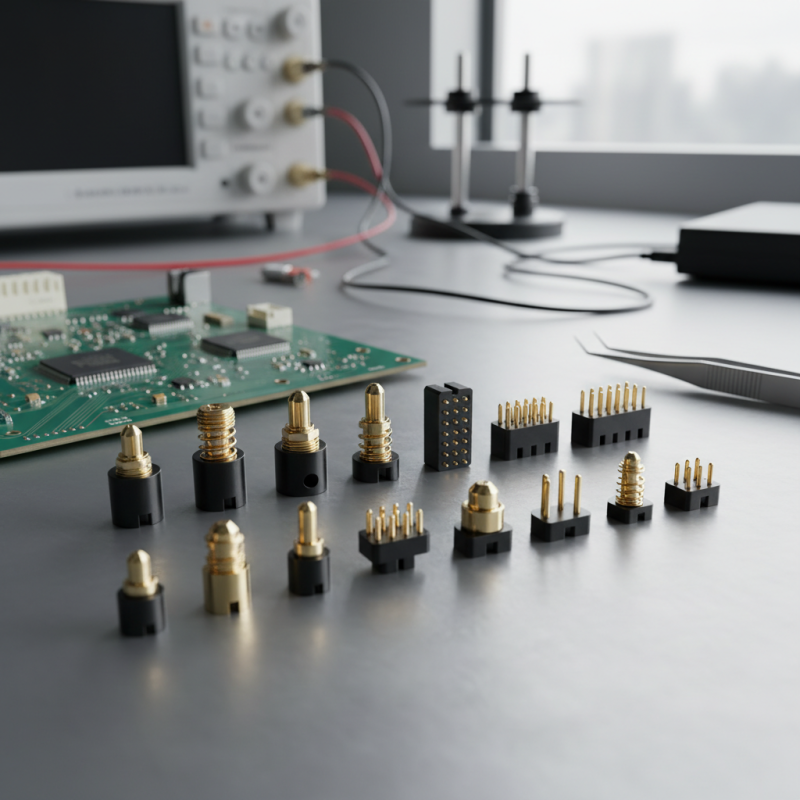

In the rapidly evolving landscape of electronic design and prototyping, the significance of reliable connectivity solutions cannot be overstated. Pogo pin receptacles have emerged as vital components in a variety of applications, providing a compact and durable interface for electrical connections. According to industry reports, the global market for pogo pin connectors is expected to reach $1.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of approximately 5.2%. This growth is driven by the increasing demand for miniaturization in electronic devices and the need for efficient testing and programming interfaces.

As electronic projects become more sophisticated, selecting the right pogo pin receptacle has become crucial for engineers and hobbyists alike. These receptacles offer numerous advantages, including high reliability, ease of assembly, and the ability to handle varying degrees of mechanical stress. The versatility of pogo pin receptacles enables their application across multiple sectors, from consumer electronics to automotive components, making them an indispensable part of modern electronic design. In this article, we will explore the top 10 pogo pin receptacles that cater to a diverse range of electronic projects, helping you make informed choices for your next innovative endeavor.

Understanding Pogo Pins: The Backbone of Efficient Electrical Connections

Pogo pins have revolutionized the way we connect electrical components in various electronic projects. These spring-loaded pins provide a reliable and efficient way to create temporary connections, making them indispensable in applications ranging from testing circuits to programming devices. Understanding the mechanics of pogo pins can elevate the design and functionality of your electronic projects, enabling you to achieve cleaner layouts and improved performance.

When selecting pogo pin receptacles, consider the type of project you're working on. The right receptacle can minimize signal degradation and enhance connection stability. Be mindful of the materials used in both the pins and receptacles; conductive metals are essential for creating optimal electrical connectivity. Additionally, proper alignment during assembly can significantly improve the reliability of the connection, reducing the risk of intermittent faults.

Tips: Always ensure that your pogo pins have adequate spring force to maintain contact with the mating surface. This not only enhances the lifespan of your project but also provides a more consistent performance. It's also beneficial to prototype with different types of pogo pin configurations to find the best fit for your specific application. Don’t overlook the importance of environmental factors as well; designing with durability in mind will keep your connections solid through various operating conditions.

Key Specifications of Pogo Pin Receptacles: A Comprehensive Overview

Pogo pin receptacles are critical components in many electronic projects, often determining the reliability and performance of device connectivity. When selecting pogo pin receptacles, key specifications such as size, pin diameter, and stroke length play a significant role in ensuring optimal function. According to recent industry reports, the demand for pogo pins in the electronics sector is projected to grow at a compound annual growth rate (CAGR) of over 5.2% through 2025, highlighting their importance in various applications, including consumer electronics, automotive, and telecommunications.

Another essential specification is the contact resistance, which typically should be lower than 20 milliohms for effective performance. This directly influences how well power is transmitted through the pins, affecting the overall efficiency of the electronic device. The materials used in the construction of pogo pin receptacles, such as gold or nickel plating, also impact durability and conductivity. As the electronics landscape evolves, the integration of advanced technologies often leads to miniaturization, necessitating receptacles that not only meet size requirements but also provide robust connectivity under varying environmental conditions. The emphasis on enhanced performance metrics is driving innovation in the design and application of pogo pin receptacles across various industries.

Top 10 Pogo Pin Receptacles: Performance Metrics and Industry Ratings

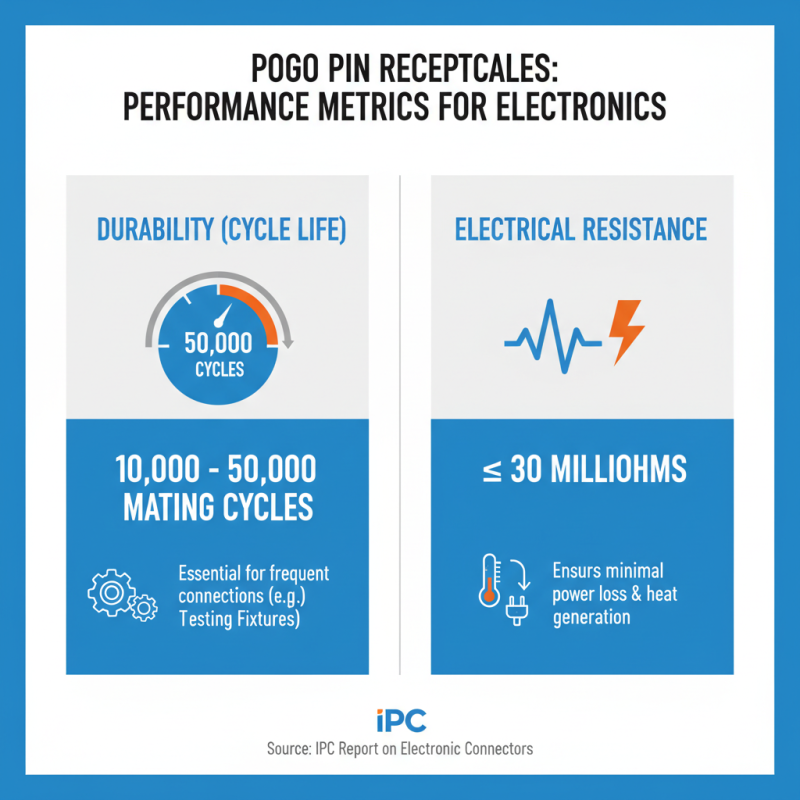

When selecting the best pogo pin receptacles for electronic projects, it is crucial to consider performance metrics that directly influence reliability and effectiveness. According to a report from the IPC (Association Connecting Electronics Industries), the average cycle life of pogo pins ranges from 10,000 to 50,000 mating cycles. This durability is essential for applications requiring frequent connections, such as in testing fixtures and automated assembly systems. Additionally, the contact resistance of high-quality pogo pin receptacles should not exceed 30 milliohms at the point of contact, ensuring minimal power loss and heat generation during operation.

In terms of industry ratings, metrics such as current carrying capability and insulation resistance also play a significant role. Research indicates that top-performing pogo pin receptacles can handle currents of up to 2 amps per pin while maintaining an insulation resistance of over 1,000 megohms. This capability is vital in applications involving high-frequency signals and sensitive electronic components, where longer-term performance stability is needed. Thus, analyzing these performance metrics and adhering to industry standards can significantly enhance the outcomes of electronic projects, paving the way for innovation and efficiency.

Applications of Pogo Pin Technology in Modern Electronic Projects

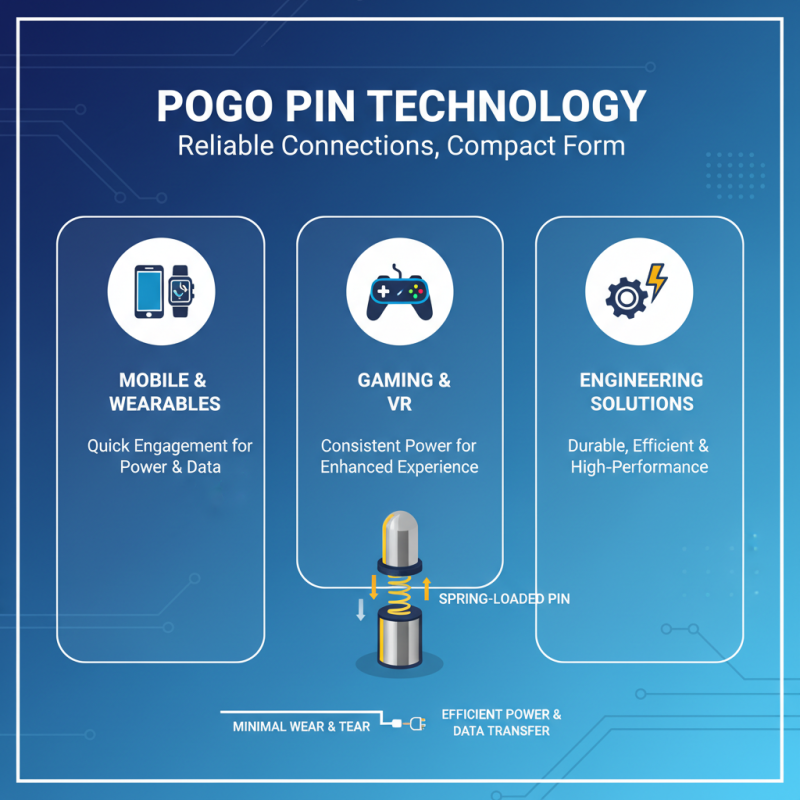

Pogo pin technology has become a vital component in a range of modern electronic projects, providing reliable connections in a compact form. These spring-loaded pins are perfect for applications that require quick engagement and disengagement, such as in mobile devices, wearable technology, and even gaming consoles. With their ability to deliver consistent power and data connections with minimal wear and tear, pogo pins are becoming the go-to choice for engineers looking for durable and efficient solutions.

When considering the integration of pogo pin receptacles in your projects, it’s essential to focus on the specific application requirements. Factors like pin configuration, spring force, and material durability can greatly impact performance. Whether you're designing a prototype or developing a consumer product, make sure to test your connections thoroughly to ensure reliability in various environments.

Tips for successful integration of pogo pins include ensuring proper alignment during assembly to prevent misfires and using appropriate materials that withstand environmental conditions. Additionally, consider the use of plating options to enhance conductivity and longevity in high-usage scenarios. By paying attention to these details, you can maximize the benefits of pogo pin technology in your electronic endeavors.

Choosing the Right Pogo Pin Receptacle for Reliability and Durability

When selecting a pogo pin receptacle for your electronic projects, reliability and durability are paramount factors to consider. The design and material composition of the receptacle can significantly affect its performance over time. Opting for receptacles made from high-quality metals and insulated materials not only provides excellent electrical conductivity but also enhances resistance to wear and tear. Look for features such as corrosion resistance and higher pin retention force, which ensure the receptacle can endure repeated connections and disconnections without losing functionality.

Another important aspect to consider is the environmental suitability of the pogo pin receptacle. Assessing the conditions in which the receptacle will operate—such as temperature extremes, humidity levels, and exposure to dust or chemicals—can guide you in choosing a product that meets specific environmental standards. Pogo pin receptacles designed for rugged applications often come with enhanced sealing and protective coatings. This added layer of durability can be crucial for maintaining reliable performance in challenging conditions, making them ideal for a wide range of electronic projects.

Related Posts

-

Solutions for Innovative Pogo Pin Array Applications in Modern Electronics

-

Exploring Pogo Pin Receptacle Innovations at the 138th Canton Fair 2025

-

What is the Importance of Pogo Pin Receptacles in Modern Electronics

-

Exploring the Versatility of Pogo Pin Receptacles for Modern Electronic Designs

-

What is Pin Pogo? Exploring Its Features, Benefits, and Uses in 2023

-

Top Strategies for Optimizing Your Pogo Pin Array Performance