Top 5 Semiconductor Curve Tracers You Need for Accurate Testing

In the rapidly evolving world of electronics, the significance of precise testing equipment cannot be overstated. Among these, the semiconductor curve tracer stands out as an essential tool for engineers and technicians alike, allowing them to analyze the electrical characteristics of semiconductor devices accurately. Renowned industry expert Dr. Emily Chen, a leading authority in semiconductor technology, emphasizes, "A high-quality semiconductor curve tracer is crucial for understanding device behavior and ensuring reliability in electronic applications."

As we venture into 2025, the demand for reliable and efficient semiconductor devices continues to rise, which makes the choice of the right curve tracer pivotal for accurate testing. In this context, this article highlights the top five semiconductor curve tracers available in the market that can empower engineers to achieve unmatched precision in their testing processes. With advancements in technology and innovative features, these tools are set to redefine the landscape of semiconductor testing, ensuring that engineers can meet the growing challenges of modern electronics.

Essential Features to Look for in Semiconductor Curve Tracers

When selecting a semiconductor curve tracer, there are several essential features you should consider to ensure accurate testing. One of the most critical aspects is the voltage and current range. A versatile curve tracer should be able to accommodate a wide range of semiconductor devices, from low-power transistors to high-voltage diodes. This flexibility allows for comprehensive testing of various components, enhancing the reliability of your results.

Another important feature to look for is the user interface and data visualization capabilities. An intuitive interface can significantly streamline the testing process, making it easier to interpret the data. Look for models that offer graphical output options, such as oscilloscope-like displays, which can provide clearer insights into the device's performance characteristics.

Tips: Always choose a curve tracer that includes advanced measurement options, such as temperature control and automatic parameter extraction. These features can save you time and increase the accuracy of your measurements, ensuring you get the most out of your testing equipment. Additionally, consider the device's connectivity options, as having software integration can enhance data analysis and storage.

Top Brands of Semiconductor Curve Tracers in 2025

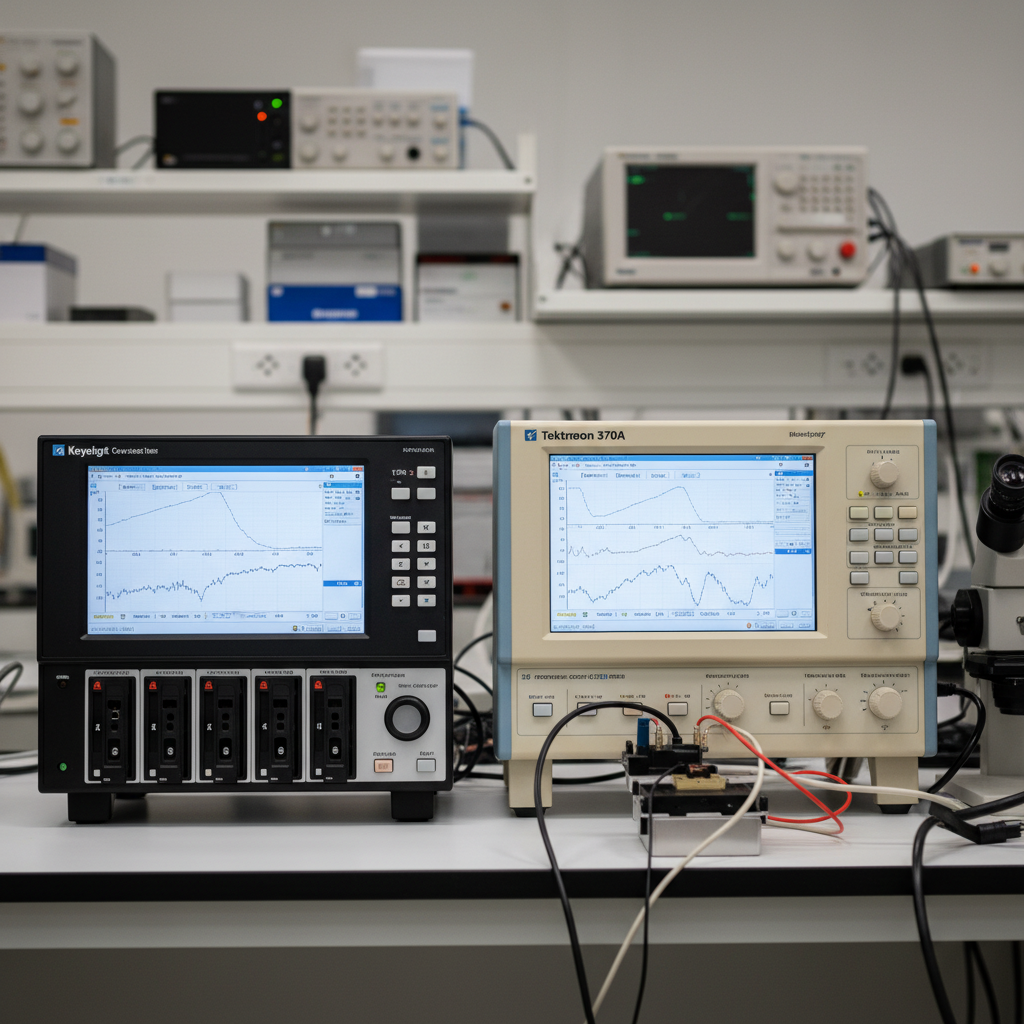

In 2025, the demand for semiconductor curve tracers has surged, driven by the increasing complexity of electronic devices and the need for precise component testing. Leading brands in the market, such as Keithley Instruments, Tektronix, and Agilent Technologies, have emerged as frontrunners due to their innovations and reliability. According to a recent report from Industry Research, the global semiconductor curve tracer market is expected to reach approximately USD 350 million by the end of 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth underscores the importance of high-quality testing equipment in ensuring the performance and integrity of semiconductor devices.

Keithley Instruments continues to dominate the sector with its advanced models, known for their superior accuracy and user-friendly interfaces. The company has reported a 15% increase in sales over the past year, attributed to the rising adoption of their curve tracers in research and development labs. Tektronix, on the other hand, is gaining traction with its innovative hybrid curve tracers that integrate both analog and digital technologies, fulfilling the evolving testing needs of semiconductor manufacturers. As the industry progresses, companies that prioritize cutting-edge technology and robust customer support are likely to lead the market, aligning with the growing emphasis on accurate and efficient testing solutions.

Comparative Analysis: Performance of the Leading Curve Tracers

When evaluating the performance of curve tracers, precise metrics are essential for achieving accurate testing of semiconductor devices. A comparative analysis reveals that the top five semiconductor curve tracers not only excel in reliability but also offer features tailored for various testing scenarios. According to a recent report by Semiconductor Insights, models such as the Keysight B1500A and Tektronix 370A stand out with their high measurement resolution and advanced data analysis capabilities. The B1500A, for instance, boasts a current measurement range down to 10 fA, making it ideal for low-power devices where traditional methods may fail.

In addition, factor analysis indicates that the speed of measurement plays a critical role in the overall effectiveness of curve tracers. The National Instruments PXI hardware platform achieves measurement speeds up to 200,000 points per second, enhancing throughput for high-volume testing environments. Meanwhile, the Rigol DG5000 series is noted for its versatility, supporting varied excitation signals which is crucial when testing complex semiconductor devices. These performance metrics not only highlight the superior capabilities of leading models but also provide insights into selecting the appropriate tool for specific testing requirements, ensuring accurate and reliable results across the board.

User Experience: Feedback from Engineers Using Curve Tracers

When it comes to selecting the right semiconductor curve tracer, user experience is paramount. Engineers who extensively use these devices often emphasize the significance of accuracy in testing results. According to a recent survey from the Semiconductor Equipment and Materials International (SEMI), over 70% of professionals reported that precision in curve tracing significantly impacts the reliability of their results. This feedback underscores the need for devices that are not only capable of providing accurate measurements but also user-friendly.

Incorporating user feedback, it’s recommended to choose a curve tracer that features intuitive interfaces and responsive support. For example, models that offer real-time data visualization can enhance the testing experience, allowing engineers to pinpoint anomalies more efficiently. Furthermore, involving engineers in product testing phases ensures that the final designs meet real-world demands, enhancing usability.

Tips for selecting a curve tracer include looking for models with multi-port capabilities, allowing for dynamic testing of multiple devices concurrently. Additionally, ensure the device is compatible with various semiconductor materials, as this flexibility can save valuable time during the testing process. Keeping these factors in mind will guide engineers in finding a curve tracer that elevates their workflow and delivers precision in testing.

Top 5 Semiconductor Curve Tracers You Need for Accurate Testing - User Experience: Feedback from Engineers Using Curve Tracers

| Model | Key Features | User Ratings (out of 5) | Feedback Summary |

|---|---|---|---|

| Model A | High-speed measurements, Graphical display | 4.8 | Engineers praised its accuracy and ease of use. |

| Model B | Automated testing, LabVIEW integration | 4.6 | Highly rated for automation features, though setup can be complex. |

| Model C | Compact design, Low power consumption | 4.5 | Favored for portability, ideal for field testing. |

| Model D | Multi-channel support, High resolution | 4.7 | Engineers appreciate the detailed outputs for complex circuits. |

| Model E | User-friendly interface, Quick measurements | 4.9 | Best rated for user experience, recommended for beginners. |

Future Trends in Semiconductor Testing Equipment and Technology

The landscape of semiconductor testing equipment is continuously evolving, driven by the increasing complexity and miniaturization of semiconductor devices. Future trends indicate a significant shift towards automation and integration of advanced analytics into testing processes. Automated curve tracers are expected to enhance testing efficiency, reducing human error while providing real-time data analysis. This integration will empower engineers to expedite their workflows, enabling quicker iterations in design and development.

Additionally, the rise of machine learning and artificial intelligence in semiconductor testing is on the horizon. These technologies promise to analyze testing data more effectively, predicting potential failures and optimizing performance metrics. As semiconductor technology advances, the need for more precise and reliable testing tools will become paramount, pushing manufacturers to innovate and provide state-of-the-art equipment. The ability to rapidly adapt testing methods to accommodate emerging technologies will be crucial for maintaining a competitive edge in the semiconductor industry.

Top 5 Semiconductor Curve Tracers for Accurate Testing

This chart represents the efficiency and accuracy levels of the top 5 semiconductor curve tracers based on testing performance metrics. The metrics include Frequency Response, Measurement Speed, and Accuracy Rate.

Related Posts

-

Unlocking Efficiency with Air Presses for Enhanced Production Processes

-

Understanding Micro Pogo Pins: The Key to Compact Electronic Connections

-

How to Optimize Your Bed of Nails Test Fixture for Maximum Efficiency

-

2025 Top 10 Burn In Socket Solutions for Enhanced Thermal Performance and Reliability

-

Top 10 Pin Pogo Sticks: Ultimate Guide to the Best Bouncing Fun!

-

10 Best IC Test Sockets for Reliable Performance in 2023