Top 10 Test Sockets for Enhanced Electrical Performance and Reliability?

In today's fast-paced technological landscape, the demand for enhanced electrical performance is at an all-time high. Test sockets play a crucial role in achieving this goal. These components are vital for efficient testing and validation of electronic devices. Their design can significantly impact the overall reliability of various applications.

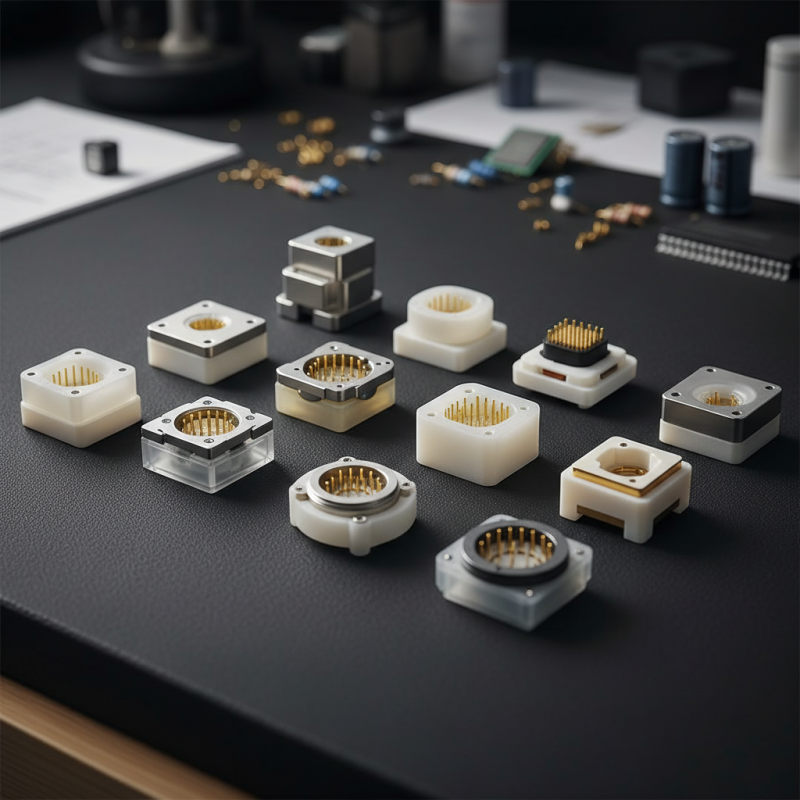

Many manufacturers offer a variety of test sockets, but not all meet the necessary standards. Selecting the right test socket can seem overwhelming. Some options may look appealing but lack the durability needed for rigorous testing. This decision can affect the quality of the final product.

Furthermore, the landscape of technology is ever-evolving. New materials and designs emerge regularly, which may introduce challenges. However, understanding the current offerings can lead to better choices. Focusing on specific criteria can help refine selections. Choosing the right test sockets will ultimately enhance performance and ensure reliability in your electronic systems.

Top 10 Test Sockets for Enhanced Electrical Performance and Reliability

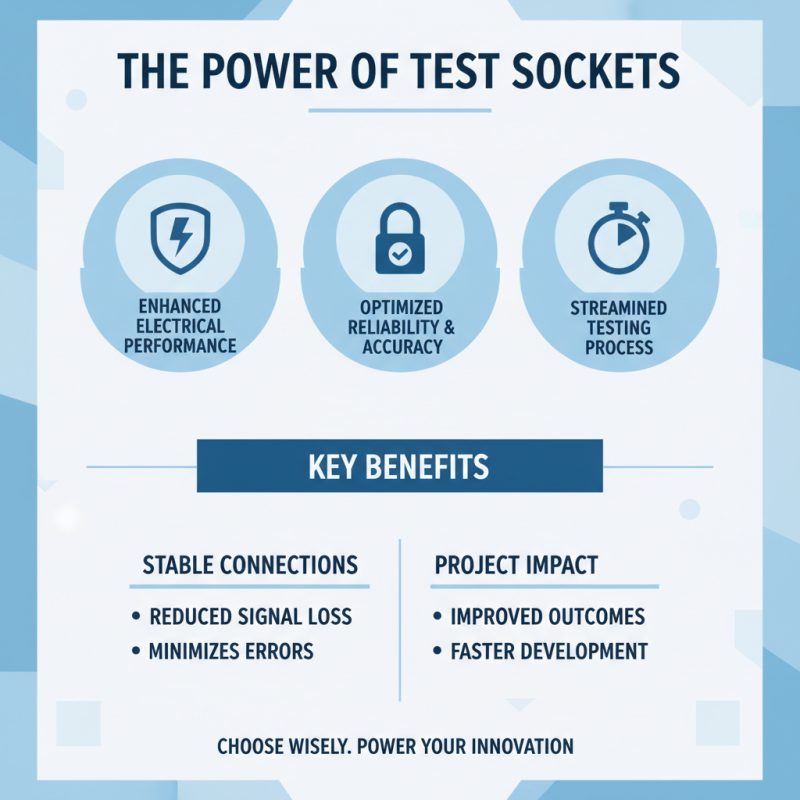

Test sockets play a crucial role in enhancing electrical performance and ensuring reliability. Choosing the right test socket can significantly impact your project outcomes. They are designed to provide stable connections and reduce signal loss. A superior test socket minimizes the risk of errors and streamlines your testing process.

When selecting a test socket, consider its temperature stability. High temperatures can affect performance negatively. Look for options that maintain their integrity under varying thermal conditions. This ensures longevity and reliability. Additionally, pay attention to the materials used in the socket construction. Durable materials stand up to frequent use and wear.

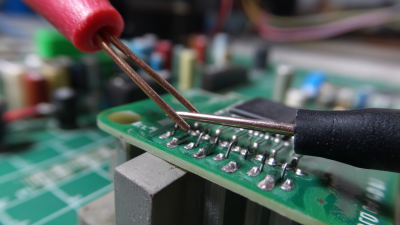

**Tip**: Ensure that the pin layout matches your testing needs precisely. Improper pin alignment can lead to frustrating failures.

Also, evaluate how easy it is to connect and disconnect your devices. Efficient operation can save time during lengthy tests.

**Tip**: Keep an eye on the specifications. Sometimes lower-cost options compromise on critical features.

It’s essential to balance cost with quality. A socket that is too cheap may not deliver the reliability needed. Implementing a few of these thoughtful practices can lead to improved performance in your electrical setups.

Understanding the Importance of Test Sockets in Electrical Engineering

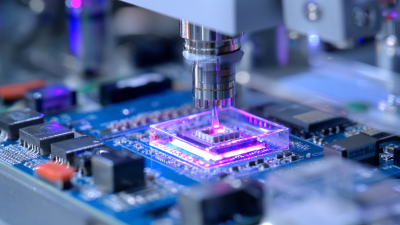

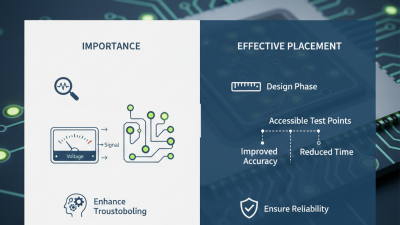

Test sockets play a vital role in electrical engineering. They provide access to electrical signals in a controlled manner, which enhances the accuracy of testing. According to a report by the Electrical Testing Association, approximately 70% of PCB failures are linked to inadequate testing procedures. This underlines the importance of quality test sockets.

A good test socket allows engineers to measure voltage, current, and resistance effectively. This precision leads to improved reliability in electronic devices. Interestingly, a study indicated that using high-quality test sockets can reduce testing time by up to 30%. This is significant for projects with tight deadlines. However, not all test sockets meet the required standards. Some may lead to inaccurate readings and costly mistakes.

Engineers must recognize this challenge. They should prioritize selecting reliable test sockets for their projects. Additionally, ongoing training in socket technologies is crucial. It keeps professionals updated with advancements in electrical testing. A well-trained team can better adapt to new technologies and improve overall performance. It's essential to reflect on these aspects for long-term success.

Top 10 Test Sockets for Enhanced Electrical Performance and Reliability

| Socket Type | Pin Configuration | Voltage Rating (V) | Current Rating (A) | Application | Material |

|---|---|---|---|---|---|

| ZIF (Zero Insertion Force) | 16 Pins | 50 | 2 | PCB Testing | Plastic |

| Burn-In Socket | 32 Pins | 100 | 5 | High-Temperature Testing | Metal |

| In-Circuit Test Socket | 20 Pins | 30 | 3 | Automated Testing | Composite |

| Socket for BGA (Ball Grid Array) | 64 Pins | 60 | 1.5 | Chip Testing | Ceramic |

| Test Socket for QFN | 24 Pins | 25 | 3 | Device Programming | High-Grade Polymer |

| Socket for LGA (Land Grid Array) | 100 Pins | 70 | 6 | Final Testing | Plastic Composite |

| Standard DIP Socket | 28 Pins | 15 | 1 | General Purpose | Plastic |

| PGA (Pin Grid Array) Socket | 64 Pins | 50 | 4 | High-Performance Computing | Metal |

| Test Socket for SOIC | 8 Pins | 20 | 2 | Integrated Circuit Testing | Polymer |

| Custom Test Socket | Varies | Varies | Varies | Specialized Applications | Customized Material |

Key Features of High-Quality Test Sockets for Electrical Applications

In the realm of electrical applications, high-quality test sockets play a crucial role in ensuring reliable performance. Key features of these sockets can greatly enhance functionality. For instance, the material used in the socket significantly affects durability. According to the Electrical Testing Association, sockets made from high-grade thermoplastics can withstand higher temperatures. This resilience is essential for minimizing breakdowns and increasing lifespan.

Another crucial aspect is contact reliability. Good test sockets offer secure connections to prevent intermittent issues. Research shows that poor contact can lead to a staggering 30% increase in testing errors. Additionally, proper shielding in test sockets helps eliminate electromagnetic interference (EMI). This feature ensures accurate readings, particularly in sensitive environments.

However, not all test sockets meet these high standards. Some may skimp on crucial features, compromising performance. Users often overlook the importance of an ergonomic design, leading to difficulties in handling during tests. A socket's overall design should promote ease of use, especially under rigorous testing conditions. Investing in quality can seem daunting. Yet, it often pays off in reduced downtime and enhanced testing accuracy.

Overview of the Top 10 Test Socket Brands: Performance and Reliability Rating

Test sockets play a crucial role in enhancing electrical performance and reliability. They ensure proper connection and efficient testing of semiconductor devices. Choosing the right test socket brand can be challenging. It's essential to know the factors influencing their performance.

Some brands excel in thermal management. This aspect greatly affects the integrity of test results. A socket that maintains stable temperatures can enhance the accuracy of electrical testing. Others focus on mechanical strength. Durability is vital, especially in high-frequency applications where wear can lead to failure.

Evaluating each brand’s reliability can be complex. Sometimes, performance ratings may not reflect real-world conditions. User feedback can be inconsistent, posing more questions than answers. Ultimately, the best choice requires careful consideration of various performance characteristics. It's important to address these uncertainties through thorough research and testing. Finding the right balance can make all the difference in achieving optimal results.

Industry Standards and Certifications for Reliable Electrical Test Sockets

When it comes to electrical test sockets, industry standards play a crucial role. High-quality test sockets must meet various certifications to ensure safety and reliability. These standards include guidelines related to voltage ratings, insulation resistance, and durability. Without proper certifications, users can face unexpected hazards.

In the quest for enhanced performance, many overlooked details impact reliability. For example, the choice of materials significantly affects the lifespan of these sockets. Additionally, designs that prioritize user convenience can sometimes compromise safety features. It's essential to reflect on these trade-offs. One must ask, are we focusing too much on performance while neglecting safety protocols?

Moreover, various testing protocols exist to validate socket performance. Regular assessments help identify potential failures before they cause major issues. The importance of routine checks cannot be overstated. However, many may underestimate this process. Keeping track of inspections is often neglected in busy environments. Inadequate attention to detail can lead to inefficiencies and risks that could be easily avoided.

Conclusion

Test sockets play a crucial role in electrical engineering by ensuring enhanced performance and reliability in testing environments. They form the backbone of various electrical applications, making it essential to understand their key features such as durability, precision, and compatibility with different devices. High-quality test sockets are designed to meet stringent industry standards and certifications, which further contributes to their reliability.

In exploring the top 10 test sockets available, the analysis highlights their performance ratings and the advancements in technology that lead to improved outcomes in electrical testing. Case studies demonstrate the significant benefits realized through the adoption of advanced test socket technologies, showcasing how they facilitate better electrical performance and reliability across various applications.

Related Posts

-

The Ultimate Guide to Selecting the Right Semiconductor Test Socket for Your Needs

-

Exploring Semiconductor Test Socket Innovations at the 138th Canton Fair 2025

-

What is Pin Pogo? Exploring Its Features, Benefits, and Uses in 2023

-

Essential Guide to Understanding the Benefits of In Circuit Testers for Electronics Projects

-

Top 10 Benefits of Wafer Probing for Semiconductor Testing?

-

2026 How to Effectively Use PCB Test Points for Reliable Circuit Testing?