12 Unbeatable Benefits of Using a Pneumatic Press for Your Manufacturing Needs

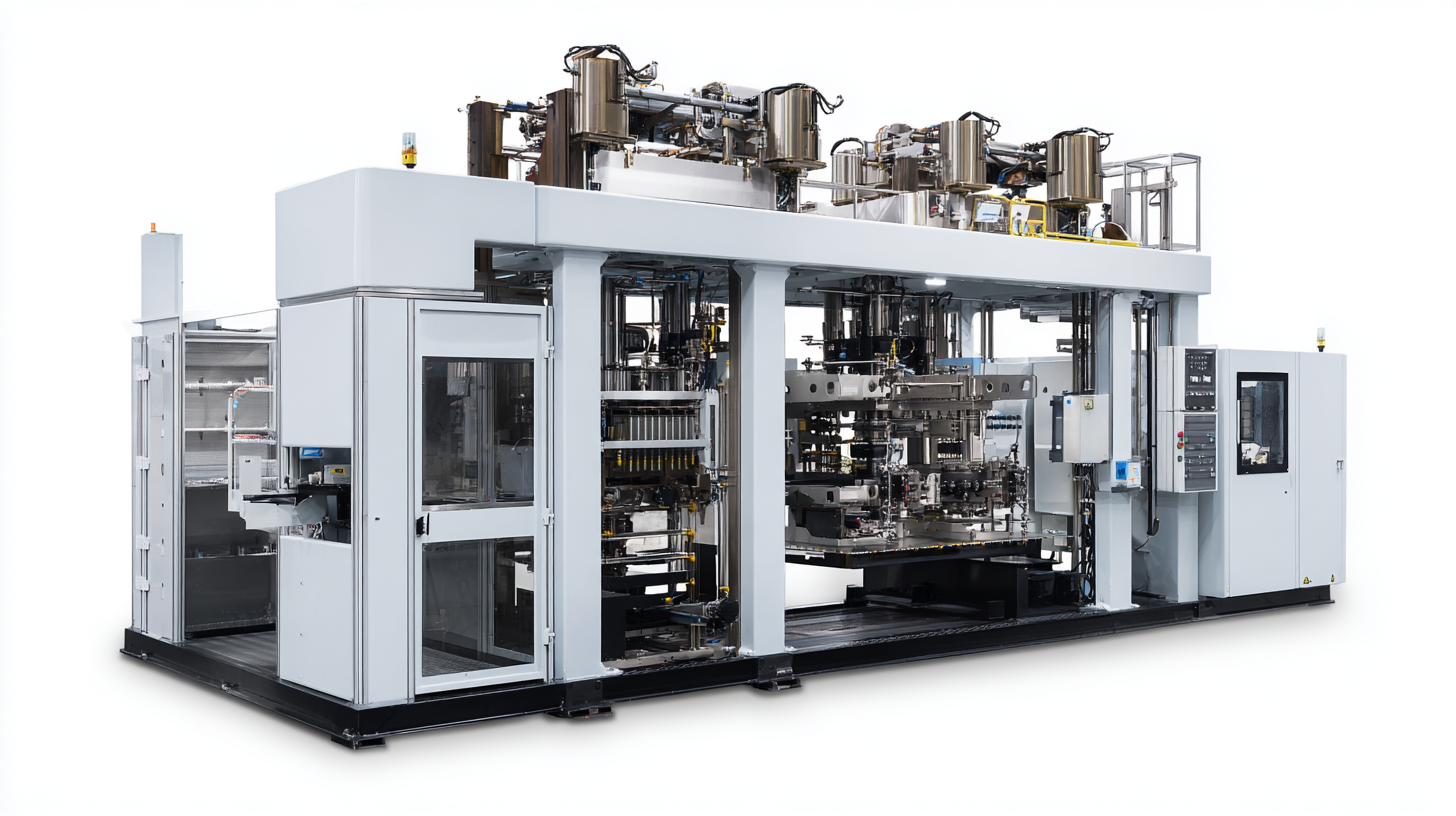

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. Among the various tools available, the pneumatic press stands out as a revolutionary solution that enhances productivity and quality. According to a report by Technavio, the global pneumatic press market is projected to witness a robust growth rate of over 5% from 2021 to 2025, driven by an increasing demand for automation and advanced manufacturing techniques. This versatile equipment not only streamlines processes but also ensures consistent output, making it an invaluable asset for manufacturers.

As industries strive to minimize downtime and maximize efficiency, the unmistakable benefits of utilizing a pneumatic press cannot be overlooked; it is an essential component in achieving operational excellence and meeting the diverse needs of modern production environments.

Unleashing Efficiency: How Pneumatic Presses Enhance Production Rates in Manufacturing

In the world of manufacturing, efficiency is paramount. Pneumatic presses have gained significant traction as a solution to meet these efficiency demands. Utilizing compressed air to power the pressing mechanism, pneumatic presses can dramatically enhance production rates. According to a report by Markets and Markets, the global pneumatic press market is projected to reach $2.1 billion by 2026, indicating a burgeoning recognition of their benefits among manufacturers. These presses not only reduce cycle times but also improve the consistency of production output, leading to decreased wastage and higher quality control.

**Tip:** When selecting a pneumatic press, consider integrating smart technology that monitors air pressure and cycles in real-time. This can lead to predictive maintenance, minimizing downtime and maintaining optimal production flow.

The versatility of pneumatic presses enables them to handle a variety of materials and applications—from forming and punching to assembly tasks. In fact, studies show that manufacturers leveraging pneumatic systems report a 20-30% increase in productivity compared to their mechanically-operated counterparts. This increase is largely attributed to faster startup times and streamlined operations.

**Tip:** Regularly train your operators on best practices for using pneumatic systems to ensure they fully understand the equipment's capabilities and how to maintain safety standards. This investment in personnel can further bolster production efficiency and product quality.

12 Unbeatable Benefits of Using a Pneumatic Press

This bar chart highlights the various benefits of using pneumatic presses in manufacturing, rated on a scale from 1 to 10. The benefits listed include increased efficiency, reduced labor costs, consistent quality, and more, showcasing how these machines enhance production rates.

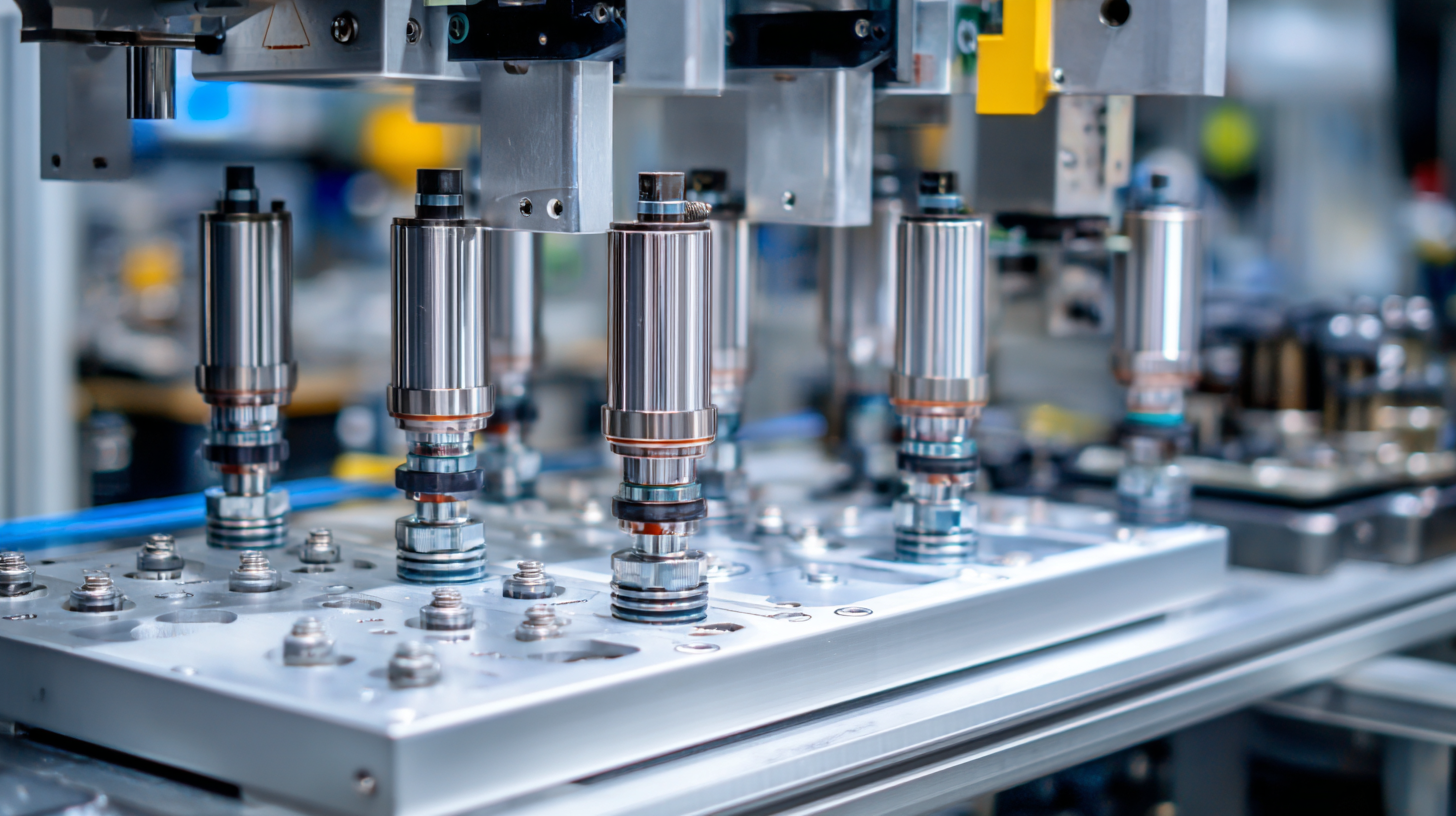

Precision Engineering: The Role of Pneumatic Presses in Achieving Tight Tolerances

Pneumatic presses have become indispensable in the realm of precision engineering, particularly when it comes to achieving tight tolerances in manufacturing. According to a report by SME, the use of pneumatic technology can increase production efficiency by as much as 30%. This is primarily due to their ability to deliver consistent force and speed during the pressing process, which is crucial for maintaining uniformity and precision in manufacturing applications. With tolerance levels often reaching as strict as ±0.001 inches, pneumatic presses allow manufacturers to meet rigorous industry standards while optimizing their workflow.

Moreover, the adaptability of pneumatic presses to different materials and applications enhances their role in precision engineering. A study published by the International Journal of Advanced Manufacturing Technology indicates that pneumatic systems minimize variability in operations, leading to improved end-product quality. This results in fewer defects and rework costs, ultimately driving down production expenses. As manufacturers continue to demand higher precision and efficiency, pneumatic presses stand out as a vital tool in achieving and maintaining tight tolerances, demonstrating their essential place in modern manufacturing processes.

Cost-Effective Operations: Analyzing the Long-term Financial Benefits of Pneumatic Presses

When analyzing the long-term financial benefits of using pneumatic presses in manufacturing, it's essential to consider their cost-effective operations. Pneumatic presses harness air pressure to efficiently perform a wide range of applications, from molding to punching. This functionality can significantly reduce energy costs, especially in an era where clean, affordable energy is increasingly important. By utilizing pneumatic systems, manufacturers can lower their utility bills and minimize downtime caused by mechanical failures.

Furthermore, pneumatic presses contribute to more sustainable manufacturing processes. Given the recent push toward decarbonization and energy efficiency, investing in this technology aligns perfectly with current trends in industrial practices. As companies strive to reduce their environmental footprints, pneumatic presses offer a viable solution that meets both operational needs and sustainability goals. In this context, the long-term financial benefits are clear: manufacturers not only save on costs but also enhance their reputation in a market that values eco-friendly practices.

Safety First: How Pneumatic Presses Improve Workplace Safety Standards in Manufacturing

Pneumatic presses have revolutionized manufacturing not only through their efficiency but also by significantly enhancing workplace safety standards. According to the National Institute for Occupational Safety and Health (NIOSH), machine-related injuries account for over 18% of workplace incidents in manufacturing. Pneumatic presses, designed with advanced safety features such as pressure-sensitive mats and emergency stop buttons, help mitigate these risks by reducing the likelihood of operator injury. The integration of these safety mechanisms ensures that operators can perform their tasks with minimal hazards, fostering a safer working environment.

Moreover, a report from the Occupational Safety and Health Administration (OSHA) highlights that companies implementing pneumatic systems often see a 40% reduction in workplace accidents. This dramatic decrease is attributed to the inherent design of pneumatic presses, which allow for smoother and more controlled operations, minimizing the risk of sudden, violent movements that can lead to injuries. Additionally, their ability to execute consistent processes with precision reduces the chances of operator fatigue and errors, further contributing to overall safety. As the manufacturing industry continues to prioritize health and safety, pneumatic presses emerge as a reliable solution that not only boosts productivity but also protects the workforce.

12 Unbeatable Benefits of Using a Pneumatic Press for Your Manufacturing Needs

| Benefit | Description | Impact on Safety |

|---|---|---|

| Increased Precision | Pneumatic presses provide consistent pressure, enhancing the precision of manufacturing processes. | Reduces risk of product defects, ensuring better safety standards for end users. |

| Less Manual Labor | Automation of pressing actions decreases the physical strain on workers. | Lower chances of workplace injuries due to repetitive tasks. |

| Enhanced Safety Features | Many pneumatic presses come with integrated safety features such as emergency stops. | Directly improves worker safety by minimizing the risk of accidents. |

| Reduced Noise Levels | Pneumatic presses tend to operate more quietly compared to mechanical alternatives. | Better work environment reduces stress and enhances focus. |

| Lower Energy Consumption | Pneumatic systems often use less energy compared to electric presses. | Lower energy costs contribute to a more sustainable manufacturing process. |

| Versatility in Applications | Pneumatic presses can be used across various manufacturing processes. | Greater adaptability leads to efficient safety measures for different products. |

| Improved Workflow | Streamlined operations lead to faster production cycles. | More efficient processes can help in maintaining safe work environments. |

| Controlled Force Application | Ability to apply precise force reduces material waste. | Minimized material waste enhances safety by reducing potential hazards from leftover materials. |

| Compact Design | Space-saving models fit into smaller workshop areas. | Safer workspaces by preventing overcrowding. |

| Easier Maintenance | Simplified design facilitates quicker and easier maintenance checks. | Improved maintenance routines contribute to overall machine safety. |

| Cost-Effectiveness | Lower operating costs compared to other pressing methods. | Financial savings can be redirected to better safety training and equipment. |

| Enhanced Product Quality | Higher quality products result from the reliable force application. | Better quality products contribute to safety standards in usage. |

Versatility in Action: Exploring the Diverse Applications of Pneumatic Presses Across Industries

Pneumatic presses are becoming increasingly vital across a variety of industries due to their versatility and efficiency in manufacturing processes. These machines utilize compressed air to generate powerful force, making them suitable for a diverse range of applications, from wood and metalworking to plastics and textiles. For instance, the global market for pneumatic presses is expected to grow significantly, with a report predicting an increase from $2.3 billion in 2022 to $3.2 billion by 2027, reflecting a compound annual growth rate (CAGR) of approximately 7.4%. This growth highlights their role in enhancing productivity and reducing operational costs.

Pneumatic presses are becoming increasingly vital across a variety of industries due to their versatility and efficiency in manufacturing processes. These machines utilize compressed air to generate powerful force, making them suitable for a diverse range of applications, from wood and metalworking to plastics and textiles. For instance, the global market for pneumatic presses is expected to grow significantly, with a report predicting an increase from $2.3 billion in 2022 to $3.2 billion by 2027, reflecting a compound annual growth rate (CAGR) of approximately 7.4%. This growth highlights their role in enhancing productivity and reducing operational costs.

One of the standout benefits of pneumatic presses is their ability to adapt to different tasks without requiring extensive reconfiguration. They can efficiently handle tasks such as forming, molding, and assembling, making them indispensable in environments where versatility is crucial. Additionally, pneumatic systems tend to have fewer moving parts, resulting in lower maintenance costs and enhanced reliability.

Tips: When considering a pneumatic press for your business, evaluate the specific applications you require to select the right model. Moreover, implementing proper air management can optimize performance and prolong the lifespan of your equipment. Lastly, training your staff on best practices can prevent injuries and improve overall workflow efficiency.

Related Posts

-

Tailored Solutions for Optimizing Your In Circuit Tester Performance

-

The Evolution of PCB Test Fixtures Shaping the Future of Electronics Manufacturing

-

Understanding the Importance of Pogo Pin Test Fixtures in Modern Electronics Manufacturing

-

Understanding the Importance of Semiconductor Testing in Modern Technology

-

Understanding the Importance of Custom Test Fixtures in Product Development

-

Innovative PCBA Testing Solutions Transforming Global Supply Chains