How to Use a Benchtop Pneumatic Press for Efficient Projects?

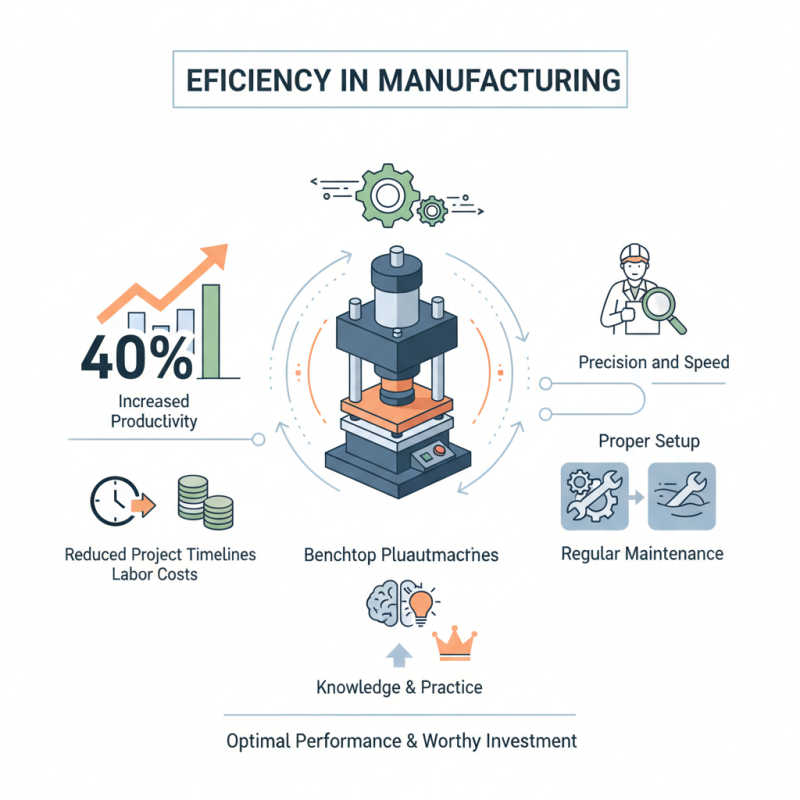

In the competitive landscape of manufacturing and fabrication, efficiency is paramount. The benchtop pneumatic press has emerged as a crucial tool for many professionals. According to a recent report from the International Association of Manufacturing, the use of pneumatic presses can enhance productivity by up to 40%. This significant improvement can transform project timelines and reduce labor costs.

Industry expert Dr. Emily Chen, renowned for her work with pneumatic automation, states, "A benchtop pneumatic press streamlines operations, allowing for precision and speed in projects." This highlights the vital role of these tools in modern workshops. However, many still overlook the importance of proper setup and maintenance, leading to suboptimal outcomes.

Mistakes can happen when working with machinery. Users may struggle with configuration, resulting in inefficiencies. Understanding these tools requires both knowledge and practice. As businesses pursue greater efficiency, the benchtop pneumatic press stands out as a worthy investment, yet it demands attention to detail for optimal performance.

Understanding Benchtop Pneumatic Press: Key Components and Features

A benchtop pneumatic press is a powerful tool known for its efficiency. The key components include a robust frame, pneumatic cylinder, and pressure regulator. The frame provides stability and supports heavy materials. A sturdy build ensures it withstands rigorous use. The pneumatic cylinder generates the force needed for pressing tasks. This design allows for consistent pressure application over time.

Features to consider are the pressure control and ease of use. Many presses include adjustable pressure settings, catering to various materials. The ability to fine-tune pressure is vital for different projects. Some presses offer safety features, preventing accidents during operation. It’s essential to understand these aspects for effective use.

Utilizing this tool can be tricky, especially for beginners. Many users encounter challenges with pressure adjustments and material placement. Over time, practice makes a difference. Effective use often requires trial and error. Reflect on mistakes to improve over time. This experience is valuable in mastering the art of pressing with a benchtop pneumatic press.

Benefits of Using a Benchtop Pneumatic Press in Various Industries

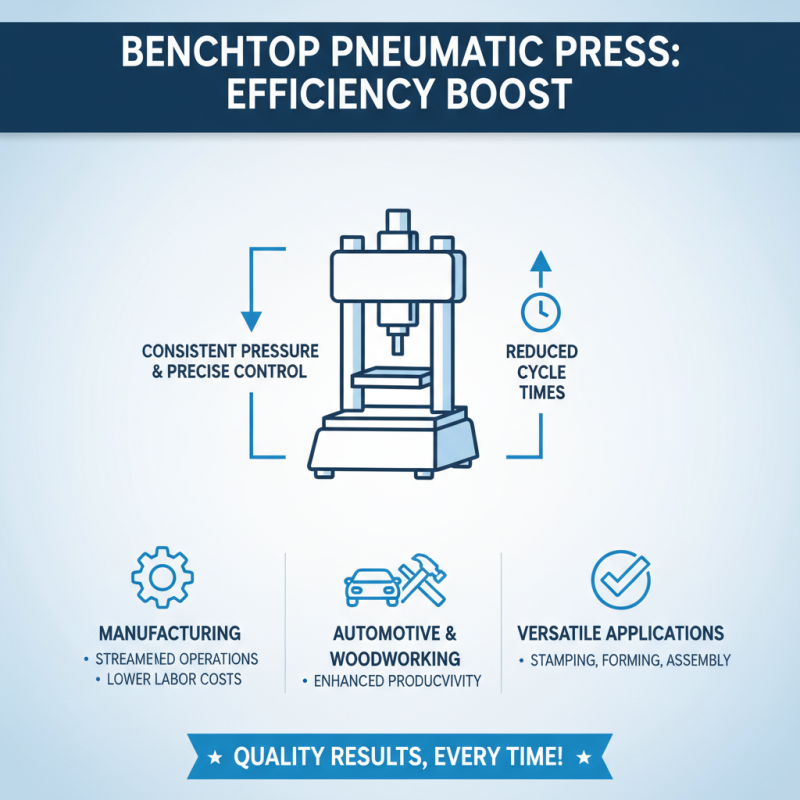

Using a benchtop pneumatic press can significantly improve production efficiency across various industries. These versatile tools are ideal for tasks like stamping, forming, and assembling. They deliver consistent pressure and precise controls, ensuring quality results every time. In manufacturing, they can streamline operations and reduce labor costs. In automotive and woodworking, the press enhances productivity by reducing cycle times.

Tips for successful operation: always ensure proper maintenance of the press. Regular checks on pressure levels and seals can prevent costly downtime. It’s crucial to maintain a clean workspace. A clutter-free area reduces risks and improves focus during complex projects. Adjusting pressure correctly is key. Too much or too little can lead to defects or safety hazards.

Consider your material type when using the press. Some materials are more sensitive to pressure changes. Practice on scrap pieces to find the optimal settings. Don’t rush through the process. Taking time to set up properly will yield better results. Sometimes it’s easy to overlook small details, leading to mistakes. Reflect on each project to improve for the next.

Step-by-Step Setup for Maximum Efficiency in Pneumatic Press Operations

A benchtop pneumatic press can significantly enhance productivity when set up correctly. Understand the key components first. A quality air compressor is essential for optimal operation, as it supplies the necessary pressure to the pneumatic system. According to industry data, pneumatic presses can achieve pressure levels exceeding 500 psi. Proper maintenance of the compressor is crucial. A poorly maintained compressor can lead to sporadic pressure, affecting performance and efficiency.

Next, focus on the setup of your pneumatic press. Begin by adjusting the pressure settings to match your project needs. Research indicates that 85% of users achieve better results by fine-tuning the pressure for specific tasks. Ensure the alignment of the workpiece is accurate. Misalignment can cause wasted materials and increase project time. Some operators overlook this step, leading to inadequate results and frustrations.

Lastly, keep safety in mind. Always use appropriate protective gear while operating the press. Reports show that improper safety measures can result in workplace injuries, impacting productivity by as much as 25%. Take a moment to reflect on your operating procedures. Identifying areas for improvement can lead to greater efficiency and fewer mistakes. Prioritize consistent evaluations of both your setup and your processes to maximize output.

Maintenance Tips to Enhance the Longevity of Your Pneumatic Press

Maintaining a benchtop pneumatic press is key to its long life and efficiency. Regular cleaning is essential. Dust and debris accumulate quickly.

Wipe down the machine after use to keep it functioning smoothly. Check for any visible wear on components. Addressing issues early can prevent bigger problems later.

Lubrication is critical but often overlooked. Use the manufacturer-recommended lubricant. A few drops can make a big difference.

However, be careful not to over-lubricate. Too much can lead to issues as well. It can cause unnecessary mess and may affect performance.

Finally, regularly inspect hoses and fittings for any leaks. A small leak can cause significant loss in pressure. This diminishes the press's effectiveness.

It’s a simple step that requires minimal effort but yields great returns. Ensuring your pneumatic press is well-maintained will enhance its longevity and efficiency on every project.

Safety Protocols and Best Practices when Operating Pneumatic Equipment

When operating a benchtop pneumatic press, safety should always come first. It’s essential to wear proper personal protective equipment. Gloves, goggles, and ear protection can help prevent injuries. Always inspect the pneumatic press before use. Check for leaks and ensure all parts are in good condition. A diligent setup minimizes risks associated with compressed air.

Moreover, understanding the equipment's limits is critical. Overloading the press can lead to dangerous situations. Adjust the pressure settings according to the material being used. Misjudgments here can result in unexpected accidents, which might be avoidable. It’s important to take breaks and reflect on the process. Rushing can lead to costly mistakes or unsafe practices. Keeping a clean workspace is equally vital. Clutter can lead to tripping hazards or difficulties in handling materials safely.

Finally, be aware of the surrounding area. Suitable ventilation is crucial when using pneumatic equipment, as it helps disperse any harmful fumes. Communicate clearly with coworkers, especially during peak operations. Sometimes the noise can be overwhelming, making it easy to overlook safety signals. Regular training sessions on safety protocols can be beneficial. Continuous learning helps ensure the safe use of pneumatic equipment.

Usage of Benchtop Pneumatic Press in Various Industries

This bar chart illustrates the percentage distribution of benchtop pneumatic press usage across different industries. It highlights how industries implement pneumatic technology to enhance efficiency in their projects.

Related Posts

-

12 Unbeatable Benefits of Using a Pneumatic Press for Your Manufacturing Needs

-

How to Choose the Best Benchtop Pneumatic Press for Your Needs

-

The Ultimate Guide to Selecting the Right PCB Test Equipment for Your Needs

-

5 Innovative PCB Test Fixture Solutions for Efficient Circuit Board Testing

-

Top 10 Test Sockets for Enhanced Electrical Performance and Reliability?

-

How to Choose the Best Semiconductor Test Socket for Your Needs?