How to Use an IV Curve Tracer for Accurate Measurements?

The accurate measurement of electrical characteristics is essential for various applications in electronics. An IV curve tracer serves as a crucial tool for analyzing devices' performance. According to a report by the International Electrotechnical Commission, precision in measuring current-voltage characteristics can lead to improved component reliability by up to 30%.

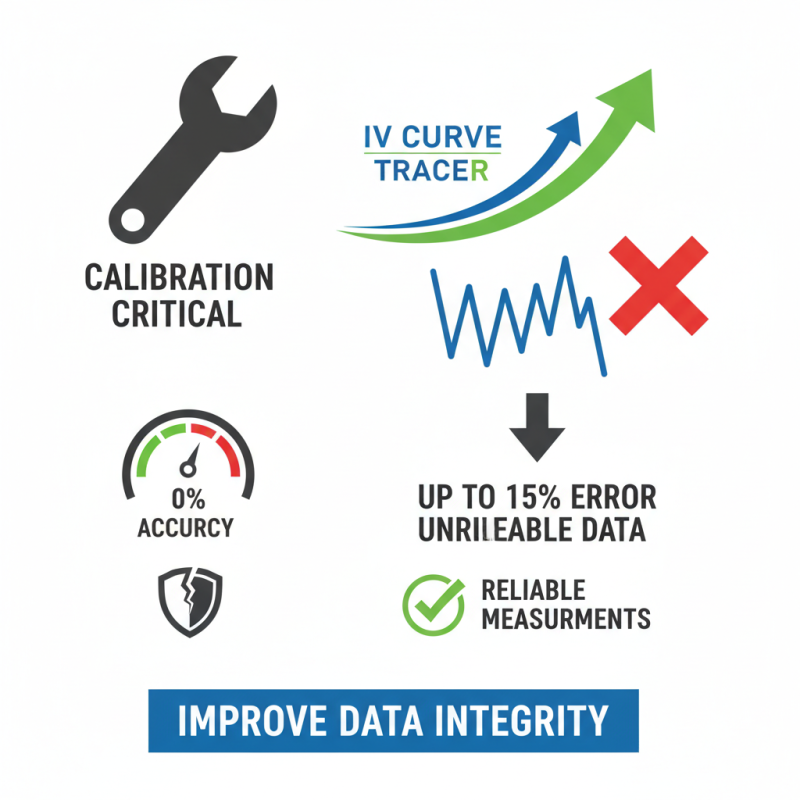

Using an IV curve tracer allows engineers to visualize these characteristics effectively. For instance, semiconductors and photovoltaic cells can be tested under various conditions. However, many users overlook the device's calibration requirements. Proper calibration can reduce measurement inaccuracies, yet it's often neglected.

Another challenge lies in interpreting the IV curves. Users may struggle to distinguish between different operational states of a device. This misunderstanding can lead to flawed conclusions about device performance. Indeed, an IV curve tracer is powerful, yet requires careful handling to maximize its capabilities. Accurate and reflective usage can reveal deeper insights into electronic components.

Understanding IV Curve Tracers and Their Importance in Measurements

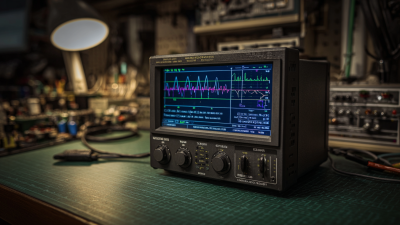

IV curve tracers are essential tools for accurately measuring the electrical characteristics of various components, especially in photovoltaics. They plot current versus voltage, showing how a device responds under different conditions. Understanding these measurements is crucial. They help optimize performance and ensure efficiency.

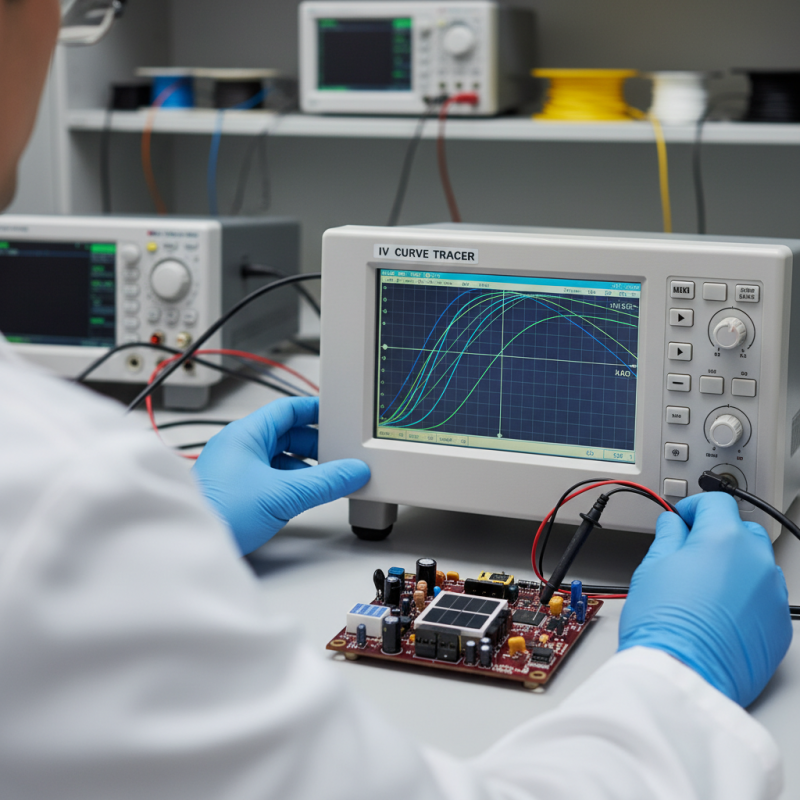

Using an IV curve tracer involves connecting it to the device, adjusting parameters, and observing data. Each point on the curve reveals information about the device's behavior. For example, the short-circuit current indicates maximum output. A more complex analysis reveals areas for improvement. Not every measurement will be perfect. Variations can stem from connection issues or device inconsistencies.

The importance of these measurements lies in their role in research and development. Engineers rely on accurate data to make informed decisions. Mistakes can lead to incorrect conclusions. Systematic testing and analysis are necessary to refine the process. Each session can present learning opportunities. This iterative approach enhances accuracy over time and contributes to better design choices.

Essential Components of an IV Curve Tracer for Accurate Data Collection

An IV curve tracer operates by applying a range of voltages to a device and measuring the resulting current. To ensure accurate measurements, several essential components are needed. The power supply must provide stable voltage levels. Variability can lead to misleading results, so precision is crucial. A good multimeter is also necessary for current measurement. The accuracy of the multimeter directly affects data quality.

Another vital component is the data acquisition system. This system captures the voltage and current readings in real-time. It's important that this system is reliable to avoid errors during data collection. Sometimes, connection issues can arise, leading to incomplete data sets. Regularly checking the connections can prevent surprises.

Lastly, a robust software interface helps visualize the results. It can highlight trends and anomalies in the data. However, software glitches can result in misinterpretations. Always double-check the software's output. Taking care of these components ensures a more accurate assessment of the IV curve, promoting better analysis and understanding of the tested devices.

IV Curve Data Analysis

This chart represents the current measured at different voltage levels using an IV curve tracer. It is crucial for analyzing the performance of photovoltaic cells and electronic components.

Step-by-Step Guide to Setting Up an IV Curve Tracer Correctly

Setting up an IV curve tracer requires careful attention to detail. Start by ensuring that the device is calibrated properly. A miscalibration can lead to significant errors in your measurements. According to a recent industry report, inaccuracies in IV measurements can reach up to 15% if calibration is neglected. This affects the reliability of your data.

Next, connect your device to the circuit. Pay attention to the polarity of your connections. Incorrect connections can result in faulty readings that mislead analysis. Some users often overlook this step, thinking it doesn’t matter. However, a simple mistake like this can produce results that are not reproducible. Ensure that all wires are secured and that there are no loose connections.

While taking measurements, observe the output closely. Sometimes, the device may show fluctuating data, indicating an issue. Monitor the ambient conditions, as humidity and temperature can also affect readings. For instance, reports suggest that temperature variations of just a few degrees Celsius can alter IV curve characteristics significantly. Make notes of any anomalies in your data to address them later.

Best Practices for Conducting Measurements with an IV Curve Tracer

Using an IV curve tracer effectively requires attention to detail. Begin by ensuring your equipment is calibrated correctly. Check the connections before starting measurements. A loose wire can lead to incorrect data.

When conducting measurements, take your time. It's easy to rush, but careful observation is key. Monitor the temperature of both the device and the environment. Variations can affect readings significantly. Document the conditions during each measurement for future reference.

Don't hesitate to repeat measurements if something seems off. Discrepancies can reveal issues you might have missed. Mistakes teach us important lessons. The experience you gain will help you refine your techniques over time. Embrace imperfections; they often lead to the most valuable insights.

Interpreting and Analyzing IV Curve Data for Improved Accuracy

Interpreting and analyzing IV curve data is crucial for obtaining accurate measurements in photovoltaic research. The IV curve depicts the current-voltage relationship of solar cells. Understanding the characteristics of this curve allows researchers to optimize performance effectively. According to a 2022 industry report by the Solar Energy Industries Association, precise IV data can enhance energy conversion efficiency by up to 15%.

When analyzing IV curve data, key parameters like open-circuit voltage and short-circuit current must be scrutinized. These metrics provide insights into device performance. For instance, a misinterpretation of the fill factor can lead to inaccuracies in efficiency projections. A study indicated that even slight variations in measurements can result in a 5% error margin in efficiency calculations.

Furthermore, environmental factors can impact the accuracy of IV curve readings. Temperature fluctuations and lighting conditions often alter the expected results. Addressing these challenges is vital for more reliable data. Some researchers have noted discrepancies due to improper calibration of the measurement equipment. Reflecting on these issues is necessary for refining methodologies and enhancing overall accuracy.

How to Use an IV Curve Tracer for Accurate Measurements?

| Measurement Point (V) | Current (A) | Power (W) | Efficiency (%) | Temperature (°C) |

|---|---|---|---|---|

| 0.0 | 0.00 | 0.00 | N/A | 25 |

| 0.5 | 0.02 | 0.01 | 10 | 25 |

| 1.0 | 0.05 | 0.05 | 25 | 25 |

| 1.5 | 0.10 | 0.15 | 35 | 26 |

| 2.0 | 0.15 | 0.30 | 50 | 27 |

| 2.5 | 0.20 | 0.50 | 60 | 28 |

Related Posts

-

Exploring IV Curve Tracers: Innovative Applications and Industry Case Studies

-

How to Use an IV Curve Tracer for Accurate Electrical Measurements

-

Tailored Solutions for Optimizing Your In Circuit Tester Performance

-

Unlocking the Secrets of IV Curve Tracers for Enhanced Electronic Testing

-

Top 5 Semiconductor Curve Tracers You Need for Accurate Testing

-

Exploring the Benefits of Pogo Pin Arrays in Modern Electronics Design